Каталог SGS инструмент для обработки алюминия - страница 49

Навигация

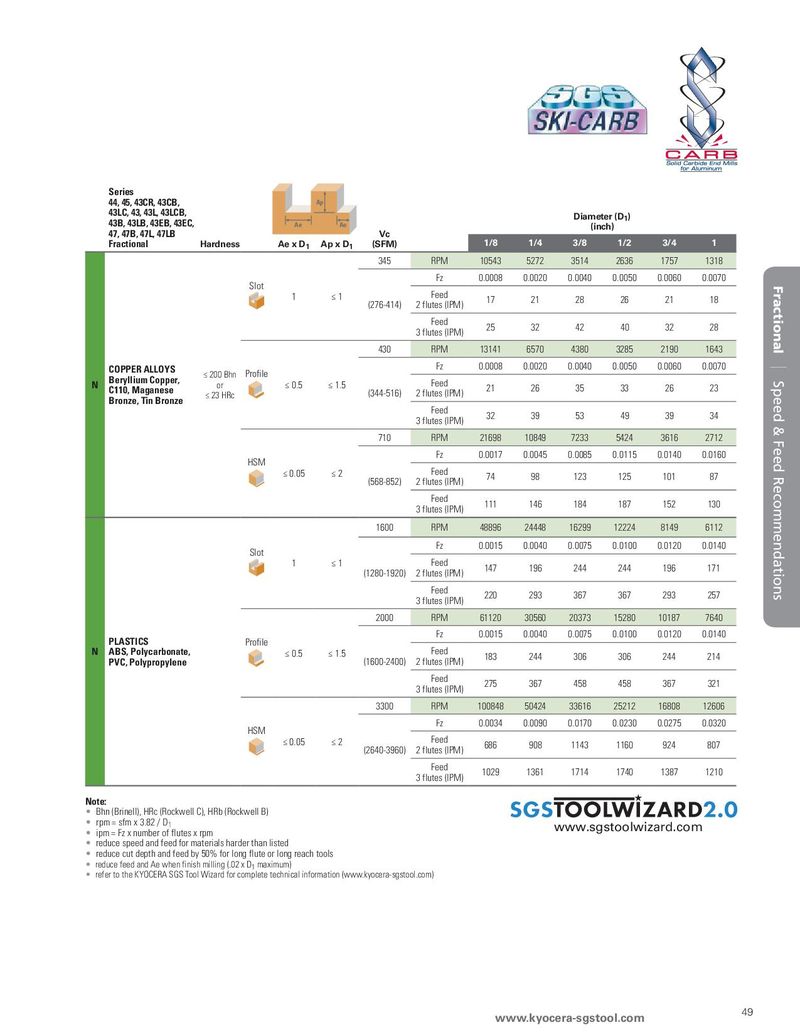

Series 44, 45, 43CR, 43CB, Ap 43LC, 43, 43L, 43LCB, Diameter (D1) 43B, 43LB, 43EB, 43EC, Ae Ae (inch) 47, 47B, 47L, 47LB Vc Fractional Hardness Ae x D1 Ap x D1 (SFM) 1/8 1/4 3/8 1/2 3/4 1 345 RPM 10543 5272 3514 2636 1757 1318 Slot Fz 0.0008 0.0020 0.0040 0.0050 0.0060 0.0070 1 ≤1 Feed 17 21 28 26 21 18 Fractional (276-414) 2 flutes (IPM) Feed 25 32 42 40 32 28 3 flutes (IPM) 430 RPM 13141 6570 4380 3285 2190 1643 COPPER ALLOYS ≤ 200 Bhn Profile Fz 0.0008 0.0020 0.0040 0.0050 0.0060 0.0070 | N Beryllium Copper, or ≤ 0.5 ≤ 1.5 Feed 21 26 35 33 26 23 Speed & Feed Recommendations C110, Maganese ≤ 23 HRc (344-516) 2 flutes (IPM) Bronze, Tin Bronze Feed 32 39 53 49 39 34 3 flutes (IPM) 710 RPM 21698 10849 7233 5424 3616 2712 HSM Fz 0.0017 0.0045 0.0085 0.0115 0.0140 0.0160 ≤ 0.05 ≤2 Feed 74 98 123 125 101 87 (568-852) 2 flutes (IPM) Feed 111 146 184 187 152 130 3 flutes (IPM) 1600 RPM 48896 24448 16299 12224 8149 6112 Slot Fz 0.0015 0.0040 0.0075 0.0100 0.0120 0.0140 1 ≤1 Feed 147 196 244 244 196 171 (1280-1920) 2 flutes (IPM) Feed 220 293 367 367 293 257 3 flutes (IPM) 2000 RPM 61120 30560 20373 15280 10187 7640 PLASTICS Profile Fz 0.0015 0.0040 0.0075 0.0100 0.0120 0.0140 N ABS, Polycarbonate, ≤ 0.5 ≤ 1.5 Feed 183 244 306 306 244 214 PVC, Polypropylene (1600-2400) 2 flutes (IPM) Feed 275 367 458 458 367 321 3 flutes (IPM) 3300 RPM 100848 50424 33616 25212 16808 12606 HSM Fz 0.0034 0.0090 0.0170 0.0230 0.0275 0.0320 ≤ 0.05 ≤2 Feed 686 908 1143 1160 924 807 (2640-3960) 2 flutes (IPM) Feed 1029 1361 1714 1740 1387 1210 3 flutes (IPM) Note: • Bhn (Brinell), HRc (Rockwell C), HRb (Rockwell B) • rpm = sfm x 3.82 / D1 www.sgstoolwizard.com • ipm = Fz x number of flutes x rpm • reduce speed and feed for materials harder than listed • reduce cut depth and feed by 50% for long flute or long reach tools • reduce feed and Ae when finish milling (.02 x D1 maximum) • refer to the KYOCERA SGS Tool Wizard for complete technical information (www.kyocera-sgstool.com) www.kyocera-sgstool.com 49

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33 Каталог SGS фрезы с переменным углом спирали Z-carb

Каталог SGS фрезы с переменным углом спирали Z-carb Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb