Каталог Sandvik инструменты для автоматов продольного точения 2018 - страница 263

Навигация

- Инструменты для автоматов продольного точения

- ТОЧЕНИЕ

- Обзор инструмента

- CoroTurn®107

- Пластины

- Инструмент для наружной обработки

- Инструмент для внутренней обработки

- T-Max®P

- Пластины

- Инструмент для наружной обработки

- Инструмент для внутренней обработки

- CoroTurn®TR

- Пластины

- Инструмент для наружной обработки

- Инструмент для внутренней обработки

- CoroCut®XS

- Пластины

- Инструмент для наружной обработки

- CoroTurn®XS

- Режущие инструменты

- Адаптеры

- CoroCut®MB

- Режущие инструменты

- Адаптеры

- ОТРЕЗКА И ОБРАБОТКА КАНАВОК

- Обзор инструмента

- CoroCut®1-2

- Пластины

- Инструмент для наружной обработки

- Инструмент для внутренней обработки

- CoroCut®QD

- Пластины

- Инструмент для наружной обработки

- CoroCut®3

- Пластины

- Инструмент для наружной обработки

- T-Max®Q-Cut

- Пластины

- Инструмент для наружной обработки

- Инструмент для внутренней обработки

- T-Max®U-Lock

- Пластины

- Инструмент для внутренней обработки

- CoroCut®XS

- Пластины

- Инструмент для наружной обработки

- CoroThread®266

- Пластины

- Инструмент для наружной обработки

- CoroTurn®XS

- Режущие инструменты

- Адаптеры

- CoroCut®MB

- Режущие инструменты

- Адаптеры

- ТОЧЕНИЕ РЕЗЬБЫ

- Обзор инструмента

- CoroThread®266

- Пластины

- Инструмент для наружной обработки

- T-Max®U-Lock

- Пластины

- Инструмент для внутренней обработки

- CoroCut®XS

- Пластины

- Инструмент для наружной обработки

- CoroTurn®XS

- Режущие инструменты

- Адаптеры

- CoroCut®MB

- Режущие инструменты

- Адаптеры

- ОСНАСТКА ДЛЯ ТОКАРНОГО ИНСТРУМЕНТА

- Призматический хвостовик

- Державки CoroTurn®XS

- Державки CoroCut®MB

- Цилиндрический хвостовик

- Оправки CoroCut®MB

- Цилиндрический хвостовик с лыской

- Оправки CoroTurn®XS с цилиндрическим хвостовиком с лысками

- Двусторонние расточные оправки CoroTurn®XS с лыской

- Расточные оправки CoroCut®MB с цилиндрическим хвостовиком с лысками

- ФРЕЗЕРОВАНИЕ

- Обзор инструмента

- Торцевые фрезы

- CoroMill®415

- Фрезы для обработки уступов

- CoroMill®490

- CoroMill®390

- Фрезы для профильной обработки

- CoroMill®300

- Фрезы для нарезания резьбы

- CoroMill®325

- Фрезы для обработки фасок

- CoroMill®495

- СВЕРЛЕНИЕ

- Свёрла со сменными головками

- CoroDrill®870

- Свёрла со сменными пластинами

- CoroDrill®880

- РАЗВЁРТЫВАНИЕ

- CoroReamer™ 830

- Цельные твердосплавные головки

- Адаптер

- ОСНАСТКА ДЛЯ ВРАЩАЮЩЕГОСЯ ИНСТРУМЕНТА

- Цилиндрический хвостовик

- Адаптеры Coromant EH с цилиндрическим хвостовиком

- ER

- Интегрированные цанги ER для Coromant EH

- ПРИНАДЛЕЖНОСТИ

- Система закрепления QS™

- Упоры для державок системы QS™

- Упоры для державок системы QS™ с подачей СОЖ под высоким давлением

- Клинья для державок системы QS™

- Сборочный элемент

- Узел подвода СОЖ

- ОБЩАЯ ИНФОРМАЦИЯ

- Алфавитный указатель

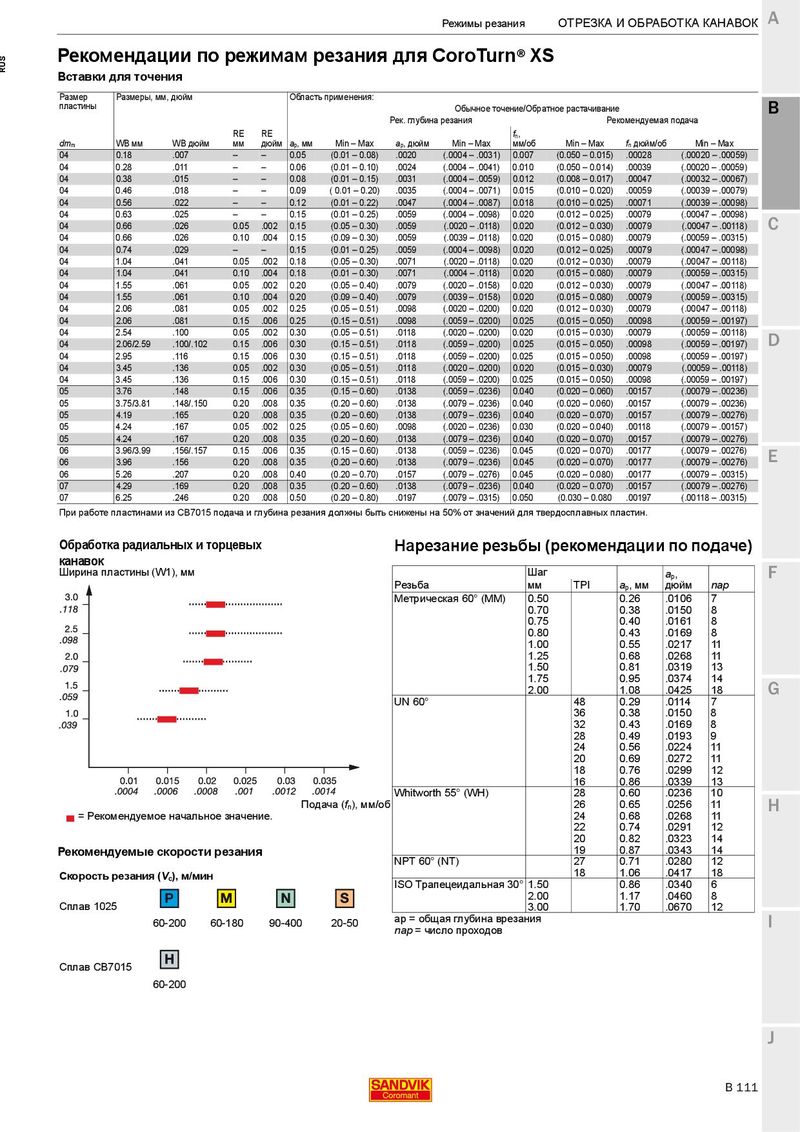

Режимы резания ОТРЕЗКА И ОБРАБОТКА КАНАВОК A Рекомендации по режимам резания для CoroTurn®XS RUS Вставки для точения Размер Размеры, мм, дюйм Область применения: пластины Обычное точение/Обратное растачивание B Рек. глубина резания Рекомендуемая подача RE RE f n , dm m WB мм WB дюйм мм дюйм a p , мм Min – Max a p , дюйм Min – Max мм/об Min – Max f n дюйм/об Min – Max 04 0.18 .007 – – 0.05 (0.01 – 0.08) .0020 (.0004 – .0031) 0.007 (0.050 – 0.015) .00028 (.00020 – .00059) 04 0.28 .011 – – 0.06 (0.01 – 0.10) .0024 (.0004 – .0041) 0.010 (0.050 – 0.014) .00039 (.00020 – .00059) 04 0.38 .015 – – 0.08 (0.01 – 0.15) .0031 (.0004 – .0059) 0.012 (0.008 – 0.017) .00047 (.00032 – .00067) 04 0.46 .018 – – 0.09 ( 0.01 – 0.20) .0035 (.0004 – .0071) 0.015 (0.010 – 0.020) .00059 (.00039 – .00079) 04 0.56 .022 – – 0.12 (0.01 – 0.22) .0047 (.0004 – .0087) 0.018 (0.010 – 0.025) .00071 (.00039 – .00098) 04 0.63 .025 – – 0.15 (0.01 – 0.25) .0059 (.0004 – .0098) 0.020 (0.012 – 0.025) .00079 (.00047 – .00098) 04 0.66 .026 0.05 .002 0.15 (0.05 – 0.30) .0059 (.0020 – .0118) 0.020 (0.012 – 0.030) .00079 (.00047 – .00118) C 04 0.66 .026 0.10 .004 0.15 (0.09 – 0.30) .0059 (.0039 – .0118) 0.020 (0.015 – 0.080) .00079 (.00059 – .00315) 04 0.74 .029 – – 0.15 (0.01 – 0.25) .0059 (.0004 – .0098) 0.020 (0.012 – 0.025) .00079 (.00047 – .00098) 04 1.04 .041 0.05 .002 0.18 (0.05 – 0.30) .0071 (.0020 – .0118) 0.020 (0.012 – 0.030) .00079 (.00047 – .00118) 04 1.04 .041 0.10 .004 0.18 (0.01 – 0.30) .0071 (.0004 – .0118) 0.020 (0.015 – 0.080) .00079 (.00059 – .00315) 04 1.55 .061 0.05 .002 0.20 (0.05 – 0.40) .0079 (.0020 – .0158) 0.020 (0.012 – 0.030) .00079 (.00047 – .00118) 04 1.55 .061 0.10 .004 0.20 (0.09 – 0.40) .0079 (.0039 – .0158) 0.020 (0.015 – 0.080) .00079 (.00059 – .00315) 04 2.06 .081 0.05 .002 0.25 (0.05 – 0.51) .0098 (.0020 – .0200) 0.020 (0.012 – 0.030) .00079 (.00047 – .00118) 04 2.06 .081 0.15 .006 0.25 (0.15 – 0.51) .0098 (.0059 – .0200) 0.025 (0.015 – 0.050) .00098 (.00059 – .00197) 04 2.54 .100 0.05 .002 0.30 (0.05 – 0.51) .0118 (.0020 – .0200) 0.020 (0.015 – 0.030) .00079 (.00059 – .00118) 04 2.06/2.59 .100/.102 0.15 .006 0.30 (0.15 – 0.51) .0118 (.0059 – .0200) 0.025 (0.015 – 0.050) .00098 (.00059 – .00197) D 04 2.95 .116 0.15 .006 0.30 (0.15 – 0.51) .0118 (.0059 – .0200) 0.025 (0.015 – 0.050) .00098 (.00059 – .00197) 04 3.45 .136 0.05 .002 0.30 (0.05 – 0.51) .0118 (.0020 – .0200) 0.020 (0.015 – 0.030) .00079 (.00059 – .00118) 04 3.45 .136 0.15 .006 0.30 (0.15 – 0.51) .0118 (.0059 – .0200) 0.025 (0.015 – 0.050) .00098 (.00059 – .00197) 05 3.76 .148 0.15 .006 0.35 (0.15 – 0.60) .0138 (.0059 – .0236) 0.040 (0.020 – 0.060) .00157 (.00079 – .00236) 05 3.75/3.81 .148/.150 0.20 .008 0.35 (0.20 – 0.60) .0138 (.0079 – .0236) 0.040 (0.020 – 0.060) .00157 (.00079 – .00236) 05 4.19 .165 0.20 .008 0.35 (0.20 – 0.60) .0138 (.0079 – .0236) 0.040 (0.020 – 0.070) .00157 (.00079 – .00276) 05 4.24 .167 0.05 .002 0.25 (0.05 – 0.60) .0098 (.0020 – .0236) 0.030 (0.020 – 0.040) .00118 (.00079 – .00157) 05 4.24 .167 0.20 .008 0.35 (0.20 – 0.60) .0138 (.0079 – .0236) 0.040 (0.020 – 0.070) .00157 (.00079 – .00276) 06 3.96/3.99 .156/.157 0.15 .006 0.35 (0.15 – 0.60) .0138 (.0059 – .0236) 0.045 (0.020 – 0.070) .00177 (.00079 – .00276) 06 3.96 .156 0.20 .008 0.35 (0.20 – 0.60) .0138 (.0079 – .0236) 0.045 (0.020 – 0.070) .00177 (.00079 – .00276) E 06 5.26 .207 0.20 .008 0.40 (0.20 – 0.70) .0157 (.0079 – .0276) 0.045 (0.020 – 0.080) .00177 (.00079 – .00315) 07 4.29 .169 0.20 .008 0.35 (0.20 – 0.60) .0138 (.0079 – .0236) 0.040 (0.020 – 0.070) .00157 (.00079 – .00276) 07 6.25 .246 0.20 .008 0.50 (0.20 – 0.80) .0197 (.0079 – .0315) 0.050 (0.030 – 0.080 .00197 (.00118 – .00315) При работе пластинами из CB7015 подача и глубина резания должны быть снижены на 50% от значений для твердосплавных пластин. Обработка радиальных и торцевых Нарезание резьбы (рекомендации по подаче) канавок Ширина пластины (W1), мм Шаг a p , F Резьба мм TPI a p , мм дюйм nap Метрическая 60° (MM) 0.50 0.26 .0106 7 0.70 0.38 .0150 8 0.75 0.40 .0161 8 0.80 0.43 .0169 8 1.00 0.55 .0217 11 1.25 0.68 .0268 11 1.50 0.81 .0319 13 1.75 0.95 .0374 14 2.00 1.08 .0425 18 G UN 60° 48 0.29 .0114 7 36 0.38 .0150 8 32 0.43 .0169 8 28 0.49 .0193 9 24 0.56 .0224 11 20 0.69 .0272 11 18 0.76 .0299 12 16 0.86 .0339 13 Whitworth 55° (WH) 28 0.60 .0236 10 Подача (f n ), мм/об 26 0.65 .0256 11 H = Рекомендуемое начальное значение. 24 0.68 .0268 11 22 0.74 .0291 12 20 0.82 .0323 14 Рекомендуемые скорости резания 19 0.87 .0343 14 NPT 60° (NT) 27 0.71 .0280 12 Скорость резания (V 18 1.06 .0417 18 c ), м/мин ISO Трапецеидальная 30° 1.50 0.86 .0340 6 P 2.00 1.17 .0460 8 Сплав 1025 3.00 1.70 .0670 12 ap = общая глубина врезания 60-200 60-180 90-400 20-50 I nap = число проходов Сплав CB7015 60-200 J ОТРЕЗКА И ОБРАБОТКА КАНАВОК Режимы резания B 111

Каталог Sandvik токарные инструменты 2020

Каталог Sandvik токарные инструменты 2020 Каталог Sandvik точение материалов высокой твердости

Каталог Sandvik точение материалов высокой твердости Каталог Sandvik вращающиеся инструменты 2017

Каталог Sandvik вращающиеся инструменты 2017 Каталог Sandvik вращающийся инструмент 2020

Каталог Sandvik вращающийся инструмент 2020 Каталог Sandvik цельный режущий инструмент 2020

Каталог Sandvik цельный режущий инструмент 2020