Общий каталог PRECITOOL - страница 16

Навигация

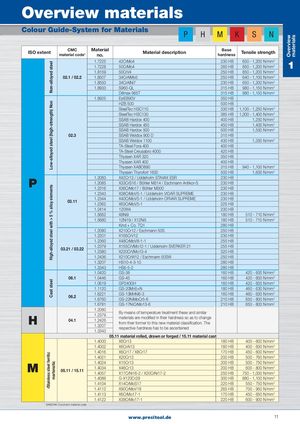

Non-alloyed steelLow-alloyed steel (high-strength) NonHigh-alloyed steel with > 5 % alloy elementsCast steelrStainless steel ferriticmartensitic BOmvoatehrrevriiweaelrswkzeuge Overview materials Colour Guide-System for Materials P H M K S N ISO extent CMC Materialmaterial code1no. Material description BasehardnessTensile strength 1.7225 42CrMo41.722850CrMo4 230 HB 650 - 1,200 N/mm2260 HB850 - 1,200 N/mm21 1.8159 50CrV4 250 HB 850 - 1,200 N/mm2 02.1 / 02.2 1.8507 34CrAlMo5 250 HB 640 - 1,100 N/mm2 1.8550 34CrAlNi7 230 HB 650 - 1,200 N/mm2 1.8933 S960-QL 315 HB 980 - 1,150 N/mm2 Dillmax 965T 315 HB 980 - 1,150 N/mm2 1.8925 EstE890V 350 HB HZB 500 500 HB SteelTec HSC110 330 HB 1,100 - 1,250 N/mm2 SteelTec HSC130 385 HB 1,300 - 1,400 N/mm2 SSAB Hardox 400 400 HB 1,250 N/mm2 SSAB Hardox 450 450 HB 1,400 N/mm2 SSAB Hardox 500 500 HB 1,550 N/mm2 02.3 SSAB Weldox 900 D 315 HB SSAB Weldox 1100 430 HB 1,350 N/mm2 TA-Steel Fora 400 400 HB TA-Steel Creusabro 4000 420 HB Thyssen XAR 320 350 HB Thyssen XAR 400 400 HB Thyssen XABO890 315 HB 940 - 1,100 N/mm2 Thyssen Thyrofort 1600 500 HB 1,600 N/mm2 P 1.2083 X42Cr13 / Uddeholm STAVAX ESR 230 HB1.2085X33CrS16 / Böhler M314 / Eschmann Antikor-S230 HB 1.2316 X36CrMo17 / Böhler M300 230 HB 1.2343 X38CrMoV5-1 / Uddeholm VIDAR SUPREME 230 HB 03.11 1.2344 X40CrMoV5-1 / Uddeholm ORVAR SUPREME1.2362X63CrMoV5-1 230 HB225 HB 1.2414 120W4 230 HB 1.5662 X8Ni9 180 HB 510 - 710 N/mm2 1.5680 12Ni19 / X12Ni5 180 HB 510 - 710 N/mm2 Kind + Co. TQ1 280 HB 1.2080 X210Cr12 / Eschmann 50S 250 HB 1.2201 X165CrV12 230 HB 1.2360 X48CrMoV8-1-1 255 HB 03.21 / 03.22 1.23791.2380X155CrVMo12-1 / Uddeholm SVERKER 21X220CrVMo13-4 255 HB320 HB 1.2436 X210CrW12 / Eschmann 50SW 250 HB 1.3207 HS10-4-3-10 280 HB 1.3343 HS6-5-2 280 HB 1.0420 GS-38 160 HB 420 - 600 N/mm2 06.1 1.0446 GS-45 160 HB 420 - 600 N/mm2 1.0619 GP240GH 160 HB 420 - 600 N/mm2 1.1120 GS-20Mn5+N 180 HB 460 - 630 N/mm2 06.2 1.6221 GS-13MnNi6-31.6760GS-22NiMoCr5-6 160 HB 460 - 630 N/mm2210 HB650 - 800 N/mm2 1.6781 GS-17NiCrMo13-6 210 HB 650 - 800 N/mm2 H 04.1 1.20801.23791.24261.3207By means of temperature treatment these and similarmaterials are modified in their hardness so as to changefrom their former to this new material classification. Therespective hardness has to be ascertained 1.3343 05.11 material rolled, drawn or forged / 15.11 material cast 1.4000 X6Cr13 180 HB 400 - 600 N/mm2 1.4002 X6CrAl13 180 HB 400 - 600 N/mm2 1.4016 X6Cr17 / X8Cr17 170 HB 450 - 600 N/mm2 1.4021 X20Cr13 200 HB 500 - 760 N/mm2 M 1.4024 X15Cr1305.11 / 15.111.40341.4057X46Cr13X17CrNi16-2 / X20CrNi17-2200 HB 500 - 750 N/mm2200 HB600 - 800 N/mm2250 HB750 - 1,000 N/mm2 1.4086 G-X120Cr29 300 HB 880 - 1,100 N/mm2 1.4104 X14CrMoS17 220 HB 550 - 750 N/mm2 1.4112 X90CrMoV18 265 HB 700 - 950 N/mm2 1.4113 X6CrMo17-1 170 HB 450 - 650 N/mm2 1.4122 X39CrMo17-1 220 HB 600 - 900 N/mm2 1 SANDVIK-Coromant material code www.precitool.de 11