Общий каталог Osawa 2021 - страница 468

Навигация

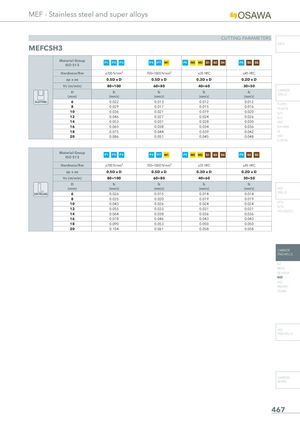

MEF - Stainless steel and super alloys CUTTING PARAMETERS INFO MEFCSH3 Material Group P1 P2 P3ISO 513 P4 P7 M1 P5 M2 M3 S1 S2 S4 P8 S3 S5 Hardness/Rm ≤700 N/mm² 700÷1000 N/mm² ≤35 HRC ≤45 HRC ap x ae 0.5D x D 0.5D x D 0.3D x D 0.2D x D Vc (m/min) 80÷100 60÷80 40÷60 30÷50 D fz(mm)(mm/z) fz(mm/z) fz(mm/z) fz(mm/z) CARBIDEDRILLS SLOTTING 6 0.022 0.013 0.012 0.012 PU-HPU 8 0.029 0.017 0.015 0.016 TA-4HTA 10 0.036 0.021 0.019 0.020 SUH 12 0.046 0.027 0.024 0.026 ALH 14 0.053 0.031 0.028 0.030 HRC 16 0.065 0.038 0.034 0.036 SUH MINI 18 0.075 0.044 0.039 0.042 HL 20 0.086 0.051 0.045 0.048 HSD C-SD-TA Material Group P1 P2 P3 P4 P7 M1 P5 M2 M3 S1 S2 S4 P8 S3 S5 ISO 513 Hardness/Rm ≤700 N/mm² 700÷1000 N/mm² ≤35 HRC ≤45 HRC ap x ae 0.5D x D 0.5D x D 0.3D x D 0.2D x D Vc (m/min) 80÷100 60÷80 40÷60 30÷50 D fz fz fz fz (mm) (mm/z) (mm/z) (mm/z) (mm/z) HSS SIDE MILLING 6 0.026 0.015 0.014 0.014 DRILLS 8 0.035 0.020 0.019 0.019 10 0.043 0.026 0.024 0.024 LFTA 12 0.055 0.033 0.031 0.031 SUTAHSS-HSS/CO 14 0.064 0.038 0.036 0.036 16 0.078 0.046 0.043 0.043 18 0.090 0.053 0.050 0.050 20 0.104 0.061 0.058 0.058 CARBIDE END-MILLS G2 MDTA HF VH/UP MEF ALU MEX/MH UH/MH HSS END-MILLS CARBIDE BURRS 467

Общий каталог Osawa 2018

Общий каталог Osawa 2018