Общий каталог Mitsubishi 2020 - 2021 - страница 982

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

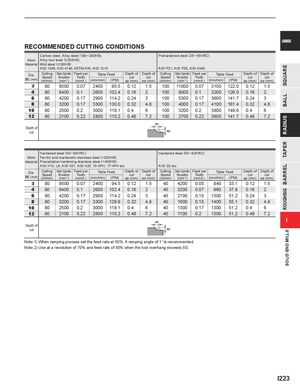

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS Carbon steel, Alloy steel (180─280HB), Prehardened steel (35─45HRC) Work Alloy tool steel (≤350HB), Material Mild steel (≤180HB) AISI 1045, AISI 4140, ASTM A36, AISI 1010 AISI P21, AISI P20, AISI 4340 Dia.DC (mm)CuttingSpeed(m/min)Main SpindleFeed perTable FeedRevolutionTooth(min-1)(mm/t.)(mm/min)(IPM)Depth ofDepth ofCuttingMain SpindleFeed perTable FeedcutcutSpeedRevolutionToothap (mm)ae (mm)(m/min)(min-1)(mm/t.)(mm/min)(IPM)Depth ofDepth ofcutcutap (mm)ae (mm) 3 80 8500 0.07 2400 95.5 0.12 1.5 100 11000 0.07 3100 122.0 0.12 1.5 4 80 6400 0.1 2600 102.4 0.16 2 100 8000 0.1 3200 126.0 0.16 2 6 80 4200 0.17 2900 114.2 0.24 3 100 5300 0.17 3600 141.7 0.24 3 8 80 3200 0.17 3300 130.0 0.32 4.8 100 4000 0.17 4100 161.4 0.32 4.8 10 80 2500 0.2 3000 118.1 0.4 6 100 3200 0.2 3800 149.6 0.4 6 12 80 2100 0.22 2800 110.2 0.48 7.2 100 2700 0.22 3600 141.7 0.48 7.2 ae Depth of cut Hardened steel (40─55HRC), Hardened steel (55─62HRC) Work Ferritic and martensitic stainless steel (>200HB), Material Precipitation hardening stainless steel (<450HB), AISI H13, L6, AISI 431, AISI 420, 15-5PH, 17-4PH etc. AISI D2 etc. Dia.DC (mm)CuttingSpeed(m/min)Main SpindleFeed perTable FeedRevolutionTooth(min-1)(mm/t.)(mm/min)(IPM)Depth ofDepth ofCuttingMain SpindleFeed perTable FeedcutcutSpeedRevolutionToothap (mm)ae (mm)(m/min)(min-1)(mm/t.)(mm/min)(IPM)Depth ofDepth ofcutcutap (mm)ae (mm) 3 80 8500 0.07 2400 94.5 0.12 1.5 40 4200 0.05 840 33.1 0.12 1.5 4 80 6400 0.1 2600 102.4 0.16 2 40 3200 0.07 960 37.8 0.16 2 6 80 4200 0.17 2900 114.2 0.24 3 40 2100 0.15 1300 51.2 0.24 3 8 80 3200 0.17 3300 129.9 0.32 4.8 40 1600 0.15 1400 55.1 0.32 4.8 10 80 2500 0.2 3000 118.1 0.4 6 40 1300 0.17 1300 51.2 0.4 6 12 80 2100 0.22 2800 110.2 0.48 7.2 40 1100 0.2 1300 51.2 0.48 7.2 ae I Depth of cut Note 1) When ramping process set the feed rate at 50%. A ramping angle of 1˚ is recommended. Note 2) Use at a revolution of 70% and feed rate of 50% when the tool overhang exceeds 5D. I223