Общий каталог Mitsubishi 2020 - 2021 - страница 97

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

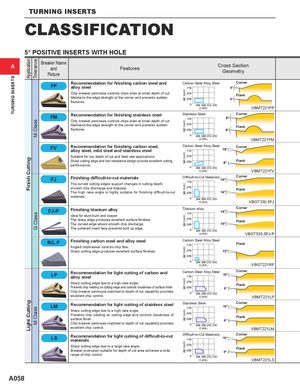

TURNING INSERTS ApplicationFinish CuttingLight Cutting ToleranceM ClassG ClassM Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION 5° POSITIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry FP Recommendation for finishing carbon steel andalloy steel Carbon Steel·Alloy Steel Corner Chip breaker peninsula controls chips even at small depth of cut.Maintains the edge strength at the corner and prevents sudden Flank fractures. f (IPR) VBMT221FP FM Recommendation for finishing stainless steel Stainless Steel Corner Chip breaker peninsula controls chips even at small depth of cut. Maintains the edge strength at the corner and prevents suddenfractures. Flank f (IPR) VBMT221FM Recommendation for finishing carbon steel, Carbon Steel·Alloy Steel Corner alloy steel, mild steel and stainless steel Suitable for low depth of cut and feed rate applications. Sharp cutting edge and low resistance design provide excellent cutting Flank performance. f (IPR) VBMT221FV Finishing difficult-to-cut materials Difficult-to-Cut Materials Corner The curved cutting edges support changes in cutting depth, smooth chip discharge and disposal. Flank The high rake angle is highly suitable for finishing difficult-to-cut materials. f (IPR) VBGT330.5FJ Finishing titanium alloy Titanium alloy Corner Ideal for aluminum and copper. The sharp edge produces excellent surface finishes. Flank The curved edge allows smooth chip discharge. The polished insert face prevents built up edge. f (IPR) VBGT330.5FJ-P Finishing carbon steel and alloy steel Carbon Steel·Alloy Steel Flank Angled chipbreaker controls chip flow. Sharp cutting edge produces excellent surface finishes. f (IPR) VBGT221RF LP Recommendation for light cutting of carbon andalloy steel Carbon Steel·Alloy Steel Corner18° Sharp cutting edge due to a high rake angle.Prevents chip welding on cutting edge and controls cloudiness of surface finish. Flank8° Chip breaker peninsula matched to depth of cut capability provides excellent chip control. f (IPR) VBMT221LP LM Recommendation for light cutting of stainless steel Stainless Steel Corner18° Sharp cutting edge due to a high rake angle. Prevents chip welding on cutting edge and controls cloudiness ofsurface finish. Flank8° Chip breaker peninsula matched to depth of cut capability provides excellent chip control. f (IPR) VBMT221LM LS Recommendation for light cutting of difficult-to-cutmaterials Difficult-to-Cut Materials Corner18° Sharp cutting edge due to a large rake angle.Breaker protrusion suitable for depth of cut area achieves a wide Flank8° range of chip control. f (IPR) VBMT221LS A058