Общий каталог Mitsubishi 2020 - 2021 - страница 95

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

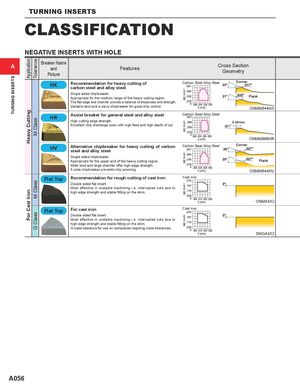

TURNING INSERTS ApplicationHeavy CuttingFor Cast Iron ToleranceM ClassM ClassG Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION NEGATIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry Recommendation for heavy cutting of Carbon Steel·Alloy Steel Corner carbon steel and alloy steel Single sided chipbreaker. Appropriate for the medium range of the heavy cutting region. Flank The flat edge and chamfer provide a balance of sharpness and strength. Variable land and a wavy chipbreaker for good chip control. f (IPR) CNMM644HX HR Assist breaker for general steel and alloy steel Carbon Steel·Alloy Steel High cutting edge strength. 0.58 mm Excellent chip discharge even with high feed and high depth of cut. 20° f (IPR) CNMM866HR Alternative chipbreaker for heavy cutting of carbon Carbon Steel·Alloy Steel Corner steel and alloy steel Single sided chipbreaker. Appropriate for the upper end of the heavy cutting region. Flank Wide land and large chamfer offer high edge strength. A wide chipbreaker prevents chip jamming. f (IPR) CNMM644HV Flat Top Recommendation for rough cutting of cast iron Cast Iron Double sided flat insert. Most effective in unstable machining i.e. interrupted cuts due to high edge strength and stable fitting on the shim. f (IPR) CNMA432 Flat Top For cast iron Cast Iron Double sided flat insert. Most effective in unstable machining i.e. interrupted cuts due to high edge strength and stable fitting on the shim. G class tolerance for use on workpieces requiring close tolerances. f (IPR) DNGA432 A056