Общий каталог Mitsubishi 2020 - 2021 - страница 89

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

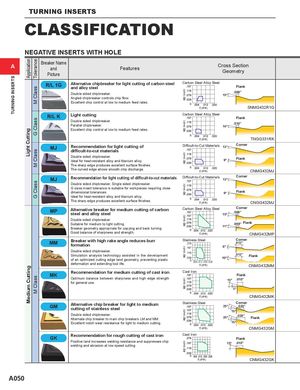

TURNING INSERTS ApplicationLight CuttingMedium Cutting ToleranceM ClassG ClassM ClassG ClassM Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION NEGATIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry Alternative chipbreaker for light cutting of carbon steel Carbon Steel·Alloy Steeland alloy steel Flank Double sided chipbreaker. .008"15° Angled chipbreaker controls chip flow. Excellent chip control at low to medium feed rates. f (IPR) SNMG432R1G Light cutting Carbon Steel·Alloy Steel Flank Double sided chipbreaker.Parallel chipbreaker. .010"14° Excellent chip control at low to medium feed rates. f (IPR) TNGG331RK Recommendation for light cutting of Difficult-to-Cut Materials 13° Corner difficult-to-cut materials Double sided chipbreaker.Ideal for heat-resistant alloy and titanium alloy. 9° Flank The sharp edge produces excellent surface finishes. The curved edge allows smooth chip discharge. f (IPR) CNMG432MJ Recommendation for light cutting of difficult-to-cut materials Difficult-to-Cut Materials 13° Corner Double sided chipbreaker, Single sided chipbreaker. G class insert tolerance is suitable for workpieces requiring close dimensional tolerances. 9° Flank Ideal for heat-resistant alloy and titanium alloy. The sharp edge produces excellent surface finishes. f (IPR) CNGG432MJ Alternative breaker for medium cutting of carbonsteel and alloy steel Carbon Steel·Alloy Steel Corner15°.006" Double sided chipbreaker. Suitable for medium to light cutting.Breaker geometry appropriate for copying and back turning. .008" Flank11° Good balance of sharpness and strength. f (IPR) CNMG432MP MM Breaker with high rake angle reduces burrformation Stainless Steel Corner.276.012".1976° Double sided chipbreaker.Simulation analysis technology assisted in the developmentof an optimized cutting edge land geometry, preventing plasticdeformation and extending tool life..118.03910°.012"Flank0.004 .012 .020 .028f (IPR)CNMG432MM MK Recommendation for medium cutting of cast iron Cast Iron Flank Optimum balance between sharpness and high edge strengthfor general use. 15° .010" 3° f (IPR) CNMG432MK GM Alternative chip breaker for light to mediumcutting of stainless steel Stainless Steel Corner25°.020"15° Double sided chipbreaker.Alternate chip breaker to main chip breakers LM and MM. 25° .020" Flank Excellent notch wear resistance for light to medium cutting. 15° f (IPR) CNMG432GM GK Recommendation for rough cutting of cast ironPositive land increases welding resistance and suppresses chipCast Ironwelding and abrasion at low speed cutting.Flank15°.010" f (IPR) CNMG432GK A050