Общий каталог Mitsubishi 2020 - 2021 - страница 77

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

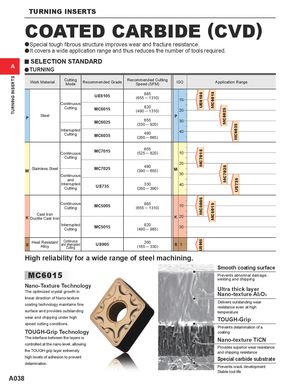

TURNING INSERTS UE6105MC7015MC5005US905 MC6015MC5015 MC6025MC7025 MC6035US735 TURNING INSERTS COATED CARBIDE (CVD) aSpecial tough fibrous structure improves wear and fracture resistance. aIt covers a wide application range and thus reduces the number of tools required. y SELECTION STANDARD A aTURNING Work Material CuttingMode Recommended Grade Recommended CuttingSpeed (SFM)ISO Application Range UE6105 985(655 ─ 1310) 10 Continuous Cutting MC6015 820(490 ─ 1310) 20 P Steel PMC602565530(330 ─ 920) InterruptedCutting MC6035 490 40(260 ─ 665) Continuous MC7015 655(525 ─ 820) 10 Cutting 20 M Stainless Steel MC7025Continuous 490(390 ─ 655) M 30 and InterruptedCutting US735 330 40(260 ─ 390) ContinuousCutting MC5005 985(655 ─ 1310) 10 Cast IronK Ductile Cast Iron K 20 InterruptedCutting MC5015 820(490 ─ 985) 30 S Heat ResistantAlloyContinuousand InterruptedCuttingUS905 260(165 ─ 330) S 5 High reliability for a wide range of steel machining. Smooth coating surface MC6015 Prevents abnormal damage,welding and chipping Nano-Texture TechnologyThe optimized crystal growth in Ultra thick layerNano-texture Al2O3 linear direction of Nano-texture coating technology maintains fine Delivers outstanding wearresistance even at high surface and provides outstanding temperature wear and chipping under high TOUGH-Grip speed cutting conditions. Prevents delamination of a TOUGH-Grip Technology coating The interface between the layers is Nano-texture TiCN controlled at the nano level, allowing Provides superior wear resistance the TOUGH-grip layer extremely and chipping resistance high levels of adhesion to prevent Special carbide substrate delamination. Prevents crack development Stable tool life A038