Общий каталог Mitsubishi 2020 - 2021 - страница 764

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

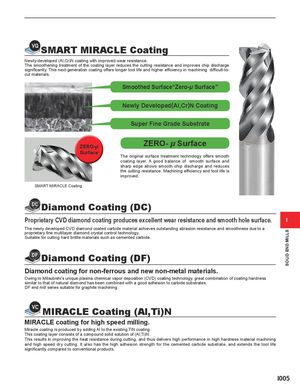

SMART MIRACLE Coating Newly-developed (Al,Cr)N coating with improved wear resistance. The smoothening treatment of the coating layer reduces the cutting resistance and improves chip discharge significantly. This next-generation coating offers longer tool life and higher efficiency in machining difficult-to- cut materials. Smoothed Surface“Zero-μ Surface” Newly Developed(Al,Cr)N Coating Super Fine Grade Substrate ZERO-µ ZERO- μ Surface Surface The original surface treatment technology offers smooth coating layer. A good balance of smooth surface and sharp edge allows smooth chip discharge and reduces the cutting resistance. Machining efficiency and tool life is improved. SMART MIRACLE Coating Diamond Coating (DC) Proprietary CVD diamond coating produces excellent wear resistance and smooth hole surface. I The newly developed CVD diamond coated carbide material achieves outstanding abrasion resistance and smoothness due to a proprietary fine multilayer diamond crystal control technology. Suitable for cutting hard brittle materials such as cemented carbide. Diamond Coating (DF) Diamond coating for non-ferrous and new non-metal materials. Owing to Mitsubishi’s unique plasma chemical vapor deposition (CVD) coating technology, great combination of coating hardness similar to that of natural diamond has been combined with a good adhesion to carbide substrates. DF end mill series suitable for graphite machining. MIRACLE Coating (Al,Ti)N MIRACLE coating for high speed milling. Miracle coating is produced by adding Al to the existing TiN coating. This coating layer consists of a compound solid solution of (Al,Ti)N. This results in improving the heat resistance during cutting, and thus delivers high performance in high hardness material machining and high speed dry cutting. It also has the high adhesion strength for the cemented carbide substrate, and extends the tool life significantly compared to conventional products. I005 SOLID END MILLS