Общий каталог Mitsubishi 2020 - 2021 - страница 718

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

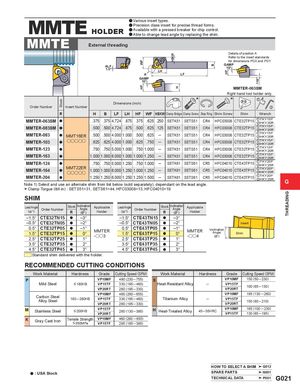

Stock WFHF HBKW H B HF .118" THREADING MMTE HOLDER a Various insert types.a Precision class insert for precise thread forms.a Available with a pressed breaker for chip control.a Able to change lead angle by replacing the shim. MMTE External threading Details of position A Refer to the insert standards for dimensions PDX and PDY. ALF1.5° LH GAMP10° A LF GAMP 10° MMTER-063SM Right hand tool holder only. Dimensions (inch) * * z Order Number Insert Number x R H B LF LH HF WF HBKW Clamp Bridge Clamp Screw Stop Ring Shim Screw Shim Wrench MMTER-063SM a .375 .375 4.724 .875 .375 .625 .250 SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-083SM a .500 .500 4.724 .875 .500 .625 .125 SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-083 a MMT16ER .500 .500 4.000 1.000 .500 .625 ─ SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-103 a ooooo .625 .625 4.000 1.000 .625 .750 ─ SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-123 a .750 .750 5.000 1.000 .750 1.000 ─ SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-163 a 1.000 1.000 6.000 1.000 1.000 1.250 ─ SETK51 SETS51 CR4 HFC03008 CTE32TP15 zTKY15FxHKY20R MMTER-124 a .750 .750 5.000 1.250 .750 1.000 ─ SETK61 SETS61 CR5 HFC04010 CTE43TP15 zTKY20FxHKY25R MMTER-164 a MMT22ERooooo 1.000 1.000 6.000 1.250 1.000 1.250 ─ SETK61 SETS61 CR5 HFC04010 CTE43TP15 zTKY20FxHKY25R MMTER-204 a 1.250 1.250 6.000 1.250 1.250 1.500 ─ SETK61 SETS61 CR5 HFC04010 CTE43TP15 zTKY20FxHKY25RNote 1) Select and use an alternate shim from list below (sold separately), dependant on the lead angle.G * Clamp Torgue (lbf-in) : SETS51=31, SETS61=44, HFC03008=13, HFC04010=19 SHIM Lead Angle(%°)Order Number Stock Inclination AngleR('°)ApplicableHolderLead Angle(%°)Order NumberStock Inclination AngleR('°)ApplicableHolder –1.5° CTE32TN15 a –3° –1.5° CTE43TN15 a –3° –0.5° CTE32TN05 a –2° –0.5° CTE43TN05 a –2° Insert 0.5° CTE32TP05 a1.5°CTE32TP15a2.5°CTE32TP25a–1°0°1°MMTER-oo30.5° CTE43TP05 a1.5°CTE43TP15a2.5°CTE43TP25a–1°0°1°MMTERInclinationAngle-oo4('°)Shim 3.5° CTE32TP35 a 2° 3.5° CTE43TP35 a 2° 4.5° CTE32TP45 a 3° 4.5° CTE43TP45 a 3° Standard shim delivered with the holder. RECOMMENDED CUTTING CONDITIONS Work Material Hardness Grade Cutting Speed (SFM) Work Material Hardness Grade Cutting Speed (SFM) P VP10MF 490 (230 ─ 755) S VP10MF 150 (50 ─ 230) Mild Steel < 180HB VP15TF 330 (195 ─ 460) Heat-Resistant Alloy ─VP20RT260 (195 ─ 330)VP15TFVP20RT100 (65 ─ 130) Carbon SteelAlloy Steel VP10MF 460 (260 ─ 655)180 ─ 280HBVP15TF330 (195 ─ 460)VP20RT260 (195 ─ 330) VP10MF 195 (130 ─ 260)Titanium Alloy─VP15TFVP20RT150 (80 ─ 210) M Stainless Steel < 200HB VP15TFVP20RT 260 (130 ─ 395) H Heat-Treated Alloy 45 ─ 55HRC VP10MFVP15TF 165 (100 ─ 230)130 (65 ─ 195) K Gray Cast Iron Tensile Strength VP10MF< 350MPaVP15TF460 (260 ─ 655)295 (195 ─ 395) HOW TO SELECT A SHIM G012 a : USA Stock SPARE PARTS N001 TECHNICAL DATA P001 G021