Общий каталог Mitsubishi 2020 - 2021 - страница 518

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

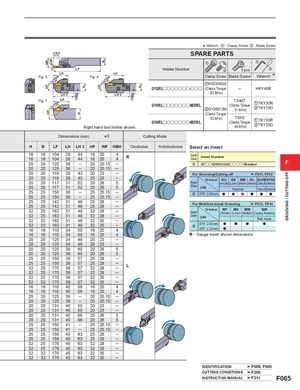

WFHFHF CW HBHH H HF B HBH H GROOVING / CUTTING OFF * Wrench : z : Clamp Screw, x : Blade Screw CDX SPARE PARTS z z LF Holder Number x 5 pcs. x LH LHFig. 3CUTDIAFig. 4CUTDIA Clamp Screw Blade Screw Wrench *zHSC05030 GYQR/Looooooo-ooo (Clamp Torque ─ HKY40R LH 2 LH 2 : 62 lbf-in) Fig. 7 LHCUTDIA GYHR/Looooooo-M20R/L TS407(Clamp TorquexGY06013M: 31 lbf-in)zTKY30RxTKY15D (Clamp Torque Right hand tool holder shown. GYHR/Looooooo-M25R/L : 53 lbf-in) TS55(Clamp Torque: 44 lbf-in)zTKY30RxTKY25D Dimensions (mm) *3 Cutting Mode H B LF LH LH 2 HF WF HBH Clockwise Anticlockwise Select an Insert 16 16 104 28 44 16 2016161042844162044R202012536─2020.15─ SeatSizeInsert NumberDGYoo0200/0224Doooo−Breaker F 20 20 125 36 ─ 20 20.15 ─ 20 20 119 28 43 20 23 ─ For Grooving/Cutting off F011, F012 20 20 119 28 43 20 23 ─20201173152202652020117315220265 SeatSize Breaker GU GS GM GL 05-GM GFGS(Gummy Steel) (Low) (Medium) (AluminumAloy) (Cutting off) (Hardenedsteel)CWNeutralHand Neutral 25 25 150 36 ─ 25 25.15 ─ D .079", 2.00 mm a a a a a a 25 25 150 36 ─ 25 25.15 ─ 25 25 142 31 49 25 28 ─252514231492528─ For Multifunctional Grooving F013, F014 32 25 162 31 49 32 28 ─322516231493228─323216231493235─ SeatSize Breaker MF MS MM BM(Finish)(Low)(Medium) (Copying, Recessing)CWBall nose 32 32 162 31 49 32 35 ─1616110345016204 D .079", 2.00 mm.088", 2.24 mmaa a a a 16 16 110 34 50 16 20 4 a : Gauge insert shown dimensions 20 20 125 34 49 20 23 ─ 20 20 125 34 49 20 23 ─ 20 20 125 39 60 20 26 5 20 20 125 39 60 20 26 5 25 25 150 39 57 25 28 ─ 25 25 150 39 57 25 28322517039573228──L 32 25 170 39 57 32 28 ─ 32 32 170 39 57 32 35 ─ 32 32 170 39 57 32 35 ─ 16 16 116 40 56 16 20 4 16 16 116 40 56 16 20 4 20 20 125 39 ─ 20 20.10 ─ 20 20 125 39 ─ 20 20.10 ─ 20 20 131 40 55 20 23 ─ 20 20 131 40 55 20 23 ─ 20 20 131 45 66 20 26 5 20 20 131 45 66 20 26 5 25 25 150 41 ─ 25 25.10 ─ 25 25 150 41 ─ 25 25.10 ─ 25 25 156 45 63 25 28 ─ 25 25 156 45 63 25 28 ─ 32 25 176 45 63 32 28 ─ 32 25 176 45 63 32 28 ─ 32 32 176 45 63 32 35 ─ 32 32 176 45 63 32 35 ─ IDENTIFICATION F008, F009 CUTTING CONDITIONS F206 INSTRUCTION MANUAL F211 F065