Общий каталог Mitsubishi 2020 - 2021 - страница 460

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

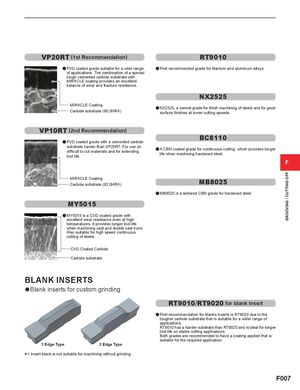

GROOVING / CUTTING OFF VP20RT (1st Recommendation) RT9010 a PVD coated grade suitable for a wide range a First recommended grade for titanium and aluminum alloys. of applications. The combination of a special tough cemented carbide substrate with MIRACLE coating provides an excellent balance of wear and fracture resistance. NX2525 MIRACLE CoatingCarbide substrate (90.5HRA) a NX2525, a cermet grade for finish machining of steels and for goodsurface finishes at lower cutting speeds. VP10RT (2nd Recommendation) BC8110 a PVD coated grade with a cemented carbide substrate harder than VP20RT. For use ondifficult to cut materials and for extendingtool life.a A CBN coated grade for continuous cutting, which provides longerlife when machining hardened steel. F MIRACLE CoatingCarbide substrate (92.0HRA) MB8025 a MB8025 is a sintered CBN grade for hardened steel. MY5015 a MY5015 is a CVD coated grade with excellent wear resistance even at high temperatures. It provides longer tool life when machining cast and ductile cast irons. Also suitable for high speed continuous cutting of steels. CVD Coated Carbide Carbide substrate BLANK INSERTS ●Blank inserts for custom grinding RT9010/RT9020 for blank insert a First recommendation for blanks inserts is RT9020 due to the tougher carbide substrate that is suitable for a wider range of applications. RT9010 has a harder substrate than RT9020 and is ideal for longer tool life on stable cutting applications. Both grades are recommended to have a coating applied that is suitable for the required application. 1 Edge Type 2 Edge Type *1 Insert blank is not suitable for machining without grinding. F007