Общий каталог Mitsubishi 2020 - 2021 - страница 436

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

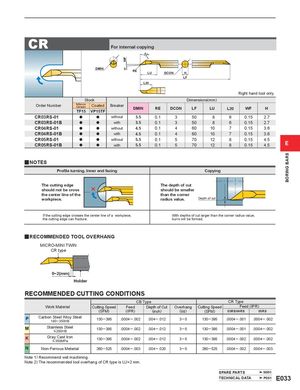

WF3° BORING BARS CR For internal copying 52° DMIN RE LU DCON H LF L20 Right hand tool only. Stock Dimensions(mm) Order Number MicroGrainCoated BreakerTF15VP15TFDMIN RE DCON LF LU L20 WF H CR03RS-01 a a without 3.5 0.1 3 50 8 6 0.15 2.7 CR03RS-01B a a with 3.5 0.1 3 50 8 6 0.15 2.7 CR04RS-01 a a without 4.5 0.1 4 60 10 7 0.15 3.6 CR04RS-01B a a with 4.5 0.1 4 60 10 7 0.15 3.6 CR05RS-01CR05RS-01B a a without 5.5 0.1 5 70 12 8 0.15 4.5aawith5.50.15701280.154.5E y NOTES Profile turning, Inner end facing Copying The cutting edge The depth of cut should not be cross should be smaller the center line of the than the corner workpiece. radius value. Depth of cut If the cutting edge crosses the center line of a workpiece, With depths of cut larger than the corner radius value, the cutting edge can fracture. burrs will be formed. y RECOMMENDED TOOL OVERHANG MICRO-MINI TWIN CR type 0~2(mm) Holder RECOMMENDED CUTTING CONDITIONS CB Type CR Type Work Material Cutting Speed Feed Depth of Cut Overhang Cutting Speed Feed (IPR) (SFM) (IPR) (inch) (l/d) (SFM) 03RS/04RS 05RS P Carbon Steel Alloy Steel180─350HB 130─395 .0004 ─.002 .004─.012 3─5 130─ 395 .0004─.001 .0004 ─.002 M Stainless Steel< 200HB 130─395 .0004 ─.002 .004─.012 3─5 130─ 395 .0004─.001 .0004 ─ .002 K Gray Cast Iron< 350MPa 130─395 .0004 ─.002 .004─.012 3─5 130─ 395 .0004─.002 .0004 ─ .002 N Non-Ferrous Meterial 260─525 .0004 ─.003 .004─.020 3─5 260─ 525 .0004─.002 .0004 ─ .003 Note 1) Recommend wet machining. Note 2) The recommended tool overhang of CR type is LU+2 mm. SPARE PARTS N001 TECHNICAL DATA P001 E033