Общий каталог Mitsubishi 2020 - 2021 - страница 424

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

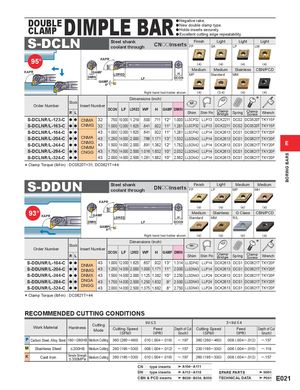

WFWF BORING BARS DOUBLE CLAMP DIMPLE BAR aNegative rake.aNew double clamp type.aHolds inserts securely.aExcellent cutting edge repeatability. S-DCLN Steel shankcoolant throughCNooinserts FinishFP LightSA LightLP LightLM 95° KAPR (4) (4) (4) (4) KAPR GAMF LDRED Medium Medium Stainless CBN/PCDHMPStandardMM DMIN LF DCON GAMP 6° Right hand tool holder shown. (4) (3,4) (4) (4) Dimensions (inch)Stock * Order Number Insert Number R L DCON LF LDRED WF H GAMF DMIN Shim Shim Pin ClampBridgeSpring ClampScrewWrench S-DCLNR/L-123-C a a CNMA 32p .750 10.000 1.219 .500 .711 12° 1.000 LLSCP32 LLP13 DCK2211 DCS2 DC0520T TKY15F S-DCLNR/L-163-C a a CNMG 32p 1.000 12.000 1.625 .641 .922 11° 1.281 LLSCP32 LLP13 DCK2211 DCS2 DC0520T TKY15F S-DCLNR/L-164-C a a 43p 1.000 12.000 1.625 .641 .922 11° 1.281 LLSCP42 LLP14 DCK2613 DCS1 DC0621T TKY20F S-DCLNR/L-204-C a a CNMA 43p 1.250 14.000 2.000 .766 1.171 13° 1.532 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F S-DCLNR/L-244-C a a CNMGCNMM 43p 1.500 14.000 2.000 .891 1.382 12° 1.782 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F E S-DCLNR/L-284-C a a CNGG 43p 1.750 14.000 2.500 1.016 1.632 10° 2.032 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F S-DCLNR/L-324-C a a 43p 2.000 14.000 2.500 1.281 1.882 10° 2.562 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F * Clamp Torque (lbf-in) : DC0520T=31, DC0621T=44 S-DDUN Steel shankcoolant throughDNooinserts FinishFP LightLP Medium MediumMPMH KAPR (4) (4) (4) (4) 93° KAPR GAMF LDRED Medium Stainless G Class CBN/PCDHStandardMMR/L DMIN LF DCON GAMP 6° Right hand tool holder shown. (4) (4) (4) (4) Dimensions (inch)Stock * Order Number Insert Number R L DCON LF LDRED WF H GAMF DMIN Shim Shim Pin ClampBridgeSpring ClampScrewWrench S-DDUNR/L-164-C a a DNMA 43p 1.000 12.000 1.625 .657 .922 13° 1.314 LLSDP42 LLP14 DCK2613 DCS1 DC0621T TKY20F S-DDUNR/L-204-C a a DNMG 43p 1.250 14.000 2.000 1.000 1.171 11° 2.000 LLSDN43 LLP14 DCK2613 DCS1 DC0621T TKY20F S-DDUNR/L-244-C a a DNMX 43p 1.500 14.000 2.000 1.125 1.382 10° 2.250 LLSDN43 LLP24 DCK2613 DCS1 DC0621T TKY20F S-DDUNR/L-284-C a a DNGA 43p 1.750 14.000 2.500 1.250 1.632 9° 2.500 LLSDN43 LLP24 DCK2613 DCS1 DC0621T TKY20F S-DDUNR/L-324-C a a DNGG 43p 2.000 14.000 2.500 1.375 1.882 8° 2.750 LLSDN43 LLP24 DCK2613 DCS1 DC0621T TKY20F * Clamp Torque (lbf-in) : DC0621T=44 RECOMMENDED CUTTING CONDITIONS Work Material Hardness CuttingMode Cutting Speed(SFM) l/d < 3Feed(IPR) 3 < l/d < 4Depth of CutCutting SpeedFeed(inch)(SFM)(IPR)Depth of Cut(inch) P Carbon Steel, Alloy Steel 180 ─280HB Medium Cutting 360 (260 ─460) .010 (.004─.016) ─ .197 360 (260─460) .008 (.004─.012) ─.157 M Stainless Steel < 200HB Medium Cutting 260 (195 ─330) .008 (.004─.012) ─.157 230 (165─ 330) .006 (.004─ .015) ─.118 K Cast Iron Tensile Strength< 350MPaMedium Cutting260 (195 ─330).010 (.004─.016) ─ .197 260 (195─330) .008 (.004─.012) ─.157 CNpp type inserts A104─A111 DNpp type inserts A112─A118 SPARE PARTS N001 CBN & PCD inserts B028─B034, B059 TECHNICAL DATA P001 E021