Общий каталог Mitsubishi 2020 - 2021 - страница 420

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

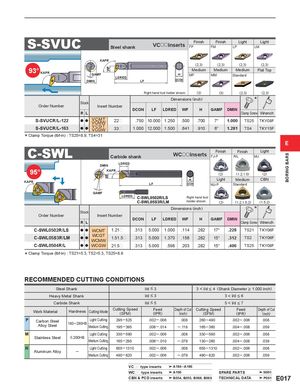

WFWF BORING BARS S-SVUC Steel shank VCooinserts FinishFP FinishFM LightLP LightLM KAPR (2,3) (2,3) (2,3) (2,3) 93° KAPR GAMF LDRED Medium Medium Medium Flat TopHMPMMStandard DMIN LF DCON Right hand tool holder shown. (3) (3) (2,3) (2,3) Stock Dimensions (inch) * Order Number Insert Number DCON LF LDRED WF H GAMF DMIN R L Clamp Screw Wrench S-SVUCR/L-122 a a VCMTVCMW 22p .750 10.000 1.250 .500 .700 7° 1.000 TS25 TKY08F S-SVUCR/L-163 a a VCGTVCGW 33p 1.000 12.000 1.500 .641 .910 6° 1.281 TS4 TKY15F * Clamp Torque (lbf-in) : TS25=8.9, TS4=31 E C-SWL Carbide shank WCooinserts FinishFJ-P Finish LightR/LMJ DMIN LDRED 95° KAPR (2) (1.2,1.5) (2) KAPR H Light Medium CBNLFDCONMJ-PStandard GAMF LDRED Right hand tool holder shown. (2) (1.2,1.5,2) (1.5,2) Stock Dimensions (inch) * Order Number Insert Number DCON LF LDRED WF H GAMF DMIN R L Clamp Screw Wrench C-SWL0502R/LS a a WCMT 1.21p .313 5.000 1.000 .114 .282 17° .228 TS21 TKY06F C-SWL05S3R/LM a a WCGTWCMW 1.51.5p .313 5.000 1.370 .156 .282 15° .312 TS2 TKY06F C-SWL0504R/L a a WCGW 21.5p .313 5.000 .598 .203 .282 15° .406 TS25 TKY08F * Clamp Torque (lbf-in) : TS21=5.3, TS2=5.3, TS25=8.9 RECOMMENDED CUTTING CONDITIONS Steel Shank l/d < 3 3 < l/d < 4 (Shank Diameter > 1.000 inch) Heavy Metal Shank l/d < 3 3 < l/d < 6 Carbide Shank l/d < 5 5 < l/d < 7 Work Material Hardness Cutting Mode Cutting Speed(SFM) Feed Depth of Cut Cutting Speed(IPR)(inch)(SFM)Feed Depth of Cut(IPR)(inch) P Carbon SteelAlloy Steel Light Cutting 295 ─525180 ─ 280HBMedium Cutting195 ─395.002─ .006.008260─490.006─.014─ .118165─360.002─ .006 .008.004─ .008.059 M Light Cutting 330 ─590 .002─.006 .008 330─590 .002─.006 .008 Stainless Steel < 200HB Medium Cutting 165 ─295 .006─ .010 ─.079 130─260 .004─.008 .039 N Light Cutting 655 ─1310 .002─.006 .008 655─1310 .002 ─ .006 .008 Aluminum Alloy ─ Medium Cutting 490 ─820 .002─ .006 ─.079 490─820 .002─.006 .059 VCpp type inserts A184─A186 WCpp type inserts A190 SPARE PARTS N001 CBN & PCD inserts B054, B055, B068, B069 TECHNICAL DATA P001 E017