Общий каталог Mitsubishi 2020 - 2021 - страница 392

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

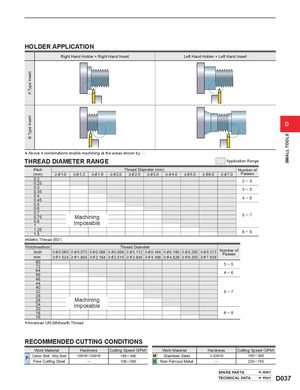

A Type InsertB Type Insert SMALL TOOLS HOLDER APPLICATION Right Hand Holder + Right Hand Insert Left Hand Holder + Left Hand Insert D * Above 4 combinations enable machining at the areas shown by p. THREAD DIAMETER RANGE Application Range Pitch Thread Diameter (mm) Number of (mm) > & 1.0 > & 1.2 > & 1.6 > & 2.0 > & 2.5 > & 3.0 > & 4.0 > & 5.0 > & 6.0 > & 7.0 Passes 0.20.25 2─4 0.30.35 3─5 0.40.45 4─6 0.5 0.6 0.70.75 Machining 5─7 0.81 Impossible 1.251.5 6─8 *Metric Thread (60°) Pitch(thread/inch) Thread Diameter Inch > & 0.060 > & 0.073 > & 0.086 > & 0.099 > & 0.112 > & 0.164 > & 0.190 > & 0.250 > & 0.313 Number ofPasses mm > & 1.524 > & 1.854 > & 2.184 > & 2.515 > & 2.845 > & 4.166 > & 4.826 > & 6.350 > & 7.938 8072 3─5 6456 4─6 48 44 40 32 5─7 28 26 Machining 2420 Impossible 18 6─8 16 *American UN,Whitworth Thread RECOMMENDED CUTTING CONDITIONS Work Material Hardness Cutting Speed (SFM) Work Material Hardness Cutting Speed (SFM) P Carbon Steel · Alloy Steel 180HB─280HB 165 ─490 M Stainless Steel < 200HB 165─ 395 Free Cutting Steel ─ 100 ─590 N Non-Ferrous Metal ─ 230─ 755 SPARE PARTS N001 TECHNICAL DATA P001 D037