Общий каталог Mitsubishi 2020 - 2021 - страница 380

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

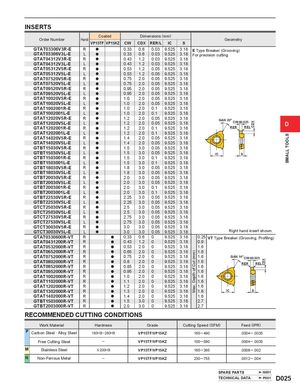

Max. Depth of Cut (mm) CDX CDX SMALL TOOLS INSERTS Coated Dimensions (mm) Order Number Hand Geometry VP15TF VP15KZ CW CDX RER/L IC S GTAT03306V3R-E R a 0.33 0.6 0.03 9.525 3.18 E Type Breaker (Grooving) GTAT03306V3L-E L a 0.33 0.6 0.03 9.525 3.18 For precision cutting GTAT04312V3R-E R a 0.43 1.2 0.03 9.525 3.18 GTAT04312V3L-E L a 0.43 1.2 0.03 9.525 3.18 GTAT05312V5R-E R a 0.53 1.2 0.05 9.525 3.18 GTAT05312V5L-E L a 0.53 1.2 0.05 9.525 3.18 GTAT07520V5R-E R a 0.75 2.0 0.05 9.525 3.18 GTAT07520V5L-E L a 0.75 2.0 0.05 9.525 3.18 GTAT09520V5R-E R a 0.95 2.0 0.05 9.525 3.18 GTAT09520V5L-E L a 0.95 2.0 0.05 9.525 3.18 GTAT10020V5R-E R a 1.0 2.0 0.05 9.525 3.18 GTAT10020V5L-E L a 1.0 2.0 0.05 9.525 3.18 GTAT1002001R-E R a 1.0 2.0 0.1 9.525 3.18 GTAT1002001L-E L a 1.0 2.0 0.1 9.525 3.18 GTAT12020V5R-E R a 1.2 2.0 0.05 9.525 3.18GTAT12020V5L-ELa1.22.00.059.5253.18 GAN 20° CW ±0.025GTAT1202001R-ERa1.22.00.19.5253.18RERRELD GTAT1202001L-E L a 1.2 2.0 0.1 9.525 3.18 GTAT14020V5R-E R a 1.4 2.0 0.05 9.525 3.18 GTAT14020V5L-E L a 1.4 2.0 0.05 9.525 3.18 GTBT15030V5R-E R a 1.5 3.0 0.05 9.525 3.18 GTBT15030V5L-E L a 1.5 3.0 0.05 9.525 3.18 IC S GTBT1503001R-E R a 1.5 3.0 0.1 9.525 3.18 GTBT1503001L-E L a 1.5 3.0 0.1 9.525 3.18 GTBT18030V5R-E R a 1.8 3.0 0.05 9.525 3.18 GTBT18030V5L-E L a 1.8 3.0 0.05 9.525 3.18 GTBT20030V5R-E R a 2.0 3.0 0.05 9.525 3.18 GTBT20030V5L-E L a 2.0 3.0 0.05 9.525 3.18 GTBT2003001R-E R a 2.0 3.0 0.1 9.525 3.18 GTBT2003001L-E L a 2.0 3.0 0.1 9.525 3.18 GTBT22530V5R-E R a 2.25 3.0 0.05 9.525 3.18 GTBT22530V5L-E L a 2.25 3.0 0.05 9.525 3.18 GTCT25030V5R-E R a 2.5 3.0 0.05 9.525 3.18 GTCT25030V5L-E L a 2.5 3.0 0.05 9.525 3.18 GTCT27530V5R-E R a 2.75 3.0 0.05 9.525 3.18 GTCT27530V5L-E L a 2.75 3.0 0.05 9.525 3.18 GTCT30030V5R-E R a 3.0 3.0 0.05 9.525 3.18 GTCT30030V5L-E L a 3.0 3.0 0.05 9.525 3.18 Right hand insert shown. GTAT0330600R-VT R a 0.33 0.6 0 9.525 3.18 0.25 VT Type Breaker (Grooving, Profiling) GTAT0431200R-VT R a 0.43 1.2 0 9.525 3.18 0.9 GTAT0532000R-VT R a 0.53 2.0 0 9.525 3.18 1.6 GTAT0652000R-VT R a 0.65 2.0 0 9.525 3.18 1.6 GTAT0752000R-VT R a 0.75 2.0 0 9.525 3.18 1.6 GAN 14° CW ±0.025 GTAT0802000R-VT R a 0.8 2.0 0 9.525 3.18 1.6GTAT0852000R-VTRa0.852.009.5253.181.6RERREL GTAT0952000R-VT R a 0.95 2.0 0 9.525 3.18 1.6 GTAT1002000R-VT R a 1.0 2.0 0 9.525 3.18 1.6 GTAT1102000R-VT R a 1.1 2.0 0 9.525 3.18 1.6 GTAT1202000R-VT R a 1.2 2.0 0 9.525 3.18 1.6 GTAT1302000R-VT R a 1.3 2.0 0 9.525 3.18 1.6 IC S GTAT1402000R-VT R a 1.4 2.0 0 9.525 3.18 1.6 GTBT1503000R-VT R a 1.5 3.0 0 9.525 3.18 2.7 GTBT2003000R-VT R a 2.0 3.0 0 9.525 3.18 2.7 RECOMMENDED CUTTING CONDITIONS Work Material Hardness Grade Cutting Speed (SFM) Feed (IPR) P Carbon Steel · Alloy Steel 180HB─280HB VP15TF/VP15KZ 165─490 .0004─.0035 Free Cutting Steel ─ VP15TF/VP15KZ 100─590 .0004─.0035 M Stainless Steel < 200HB VP15TF/VP15KZ 165─395 .0008─.002 N Non-Ferrous Metal ─ VP15TF/VP15KZ 230─755 .0012─.004 SPARE PARTS N001 TECHNICAL DATA P001 D025