Общий каталог Mitsubishi 2020 - 2021 - страница 349

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

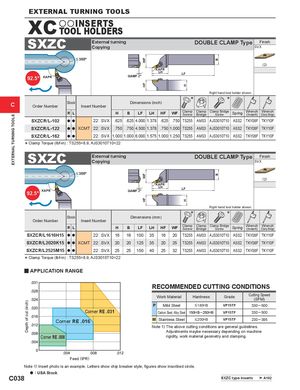

EXTERNAL TURNING TOOLS Depth of cut (inch) WFHFWFHF HH BB EXTERNAL TURNING TOOLS XC iiINSERTS TOOL HOLDERS SXZC External turningCopying DOUBLE CLAMP Type FinishSVX < 300° (2) KAPR 92.5° KAPR LHGAMF 2° LF Right hand tool holder shown. C StockOrder NumberInsert Number Dimensions (inch) * * R L H B LF LH HF WF ClampScrew ClampBridgeClamp BridgeScrewSpringWrench(Insert)Wrench(Clamp Bridge) SXZCR/L-102 a a 22pSVX .625 .625 4.000 1.378 .625 .750 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F SXZCR/L-122 a a XCMT 22pSVX .750 .750 4.500 1.378 .750 1.000 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F SXZCR/L-162 a a 22pSVX 1.000 1.000 6.000 1.575 1.000 1.250 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F * Clamp Torque (lbf-in) : TS255=8.9, AJS3010T10=22 SXZC External turningCopying DOUBLE CLAMP Type FinishSVX < 300° (2) KAPR 92.5° KAPR LHGAMF 2° LF Right hand tool holder shown. Stock Dimensions (mm) * * Order Number Insert Number R L H B LF LH HF WF ClampScrew ClampBridgeClamp BridgeScrewSpringWrench(Insert)Wrench(Clamp Bridge) SXZCR/L1616H15 a a 22pSVX 16 16 100 35 16 20 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F SXZCR/L2020K15 a a XCMT 22pSVX 20 20 125 35 20 25 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F SXZCR/L2525M15 a a 22pSVX 25 25 150 40 25 32 TS255 AMS3 AJS3010T10 ASS2 TKY08F TKY10F * Clamp Torque (lbf-in) : TS255=8.9, AJS3010T10=22 y APPLICATION RANGE RECOMMENDED CUTTING CONDITIONS Work Material Hardness Grade Cutting Speed(SFM) P Mild Steel < 180HB VP15TF 330 ─ 500 Corner RE .031 Carbon Steel, Alloy Steel 150HB ─ 250HB VP15TF 330 ─ 500 Corner RE .016 M Stainless Steel < 200HB VP15TF 230 ─ 395 Note 1) The above cutting conditions are general guidelines. Adjustments maybe necessary depending on machine Corner RE .008 rigidity, work material geometry and clamping. Feed (IPR) Note 1) Insert photo is an example. Letters show chip breaker style, figures show inscribed circle. a : USA Stock C038 SXZC type inserts A192