Общий каталог Mitsubishi 2020 - 2021 - страница 240

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

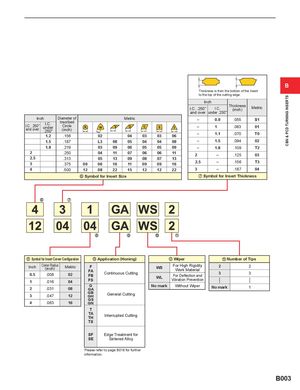

CBN & PCD TURNING INSERTS B Thickness is from the bottom of the insert to the top of the cutting edge. Inch I.C. .250"and overI.C.under .250"Thickness(inch)Metric Inch Diameter ofI.C. .250"and overI.C.under.250"InscribedCircle(inch)1.2.15602Metric – 0.9 .055 S1–1.0630104030306–1.1.070T0 1.5 .187 L3 08 05 04 04 08 – 1.5 .094 02 1.8 .219 03 09 06 05 05 09 – 1.8 .109 T2 2 .250 04 11 07 06 06 11 2 – .125 03 2.5 .313 05 13 09 08 07 13 3 .375 09 06 16 11 09 09 16 2.5 – .156 T3 4 .500 12 08 22 15 12 12 22 3 – .187 04 n Symbol for Insert Size m Symbol for Insert Thickness , Symbol for Insert Corner Configuration . Application (Honing) / Wiper Number of Tips Inch Corner Radius(inch)Metric0.5.00802FFAFB Continuous Cutting1.01604FS WS For High RigidityWork Material2WLFor Deflection andVibration Prevention323 G2.03108GA No mark Without Wiper No mark 1 3 .047 12 GBGH General Cutting GS 4 .063 16 GN T TATH Interrupted Cutting TS SF Edge Treatment for SE Sintered Alloy Please refer to page B016 for further information. B003