Общий каталог Mitsubishi 2020 - 2021 - страница 227

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

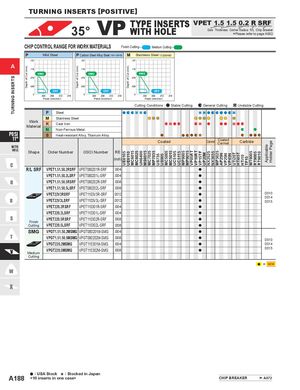

TURNING INSERTS Depth of Cut (mm) Depth of Cut (mm) UE6105 Depth of Cut (mm)UE6110 MC6015 MC6025 UH6400 MS6015 MC7025 MP7035 US735 US905 MC5005 MC5015 UC5105 UC5115 MP9005 MP9015 VP05RT VP10RT VP15TF UP20M NX2525 NX3035 MP3025 AP25N VP25N VP45N UTi20T HTi05T HTi10 TF15 MT9005 RT9005 RT9010 Applicable Holder Page TURNING INSERTS [POSITIVE] 35° VP TYPEWITH INSERTSHOLE VPET 1.5 1.5 0.2 R SRFSizeThickness Corner Radius R/L Chip Breaker*Please refer to page A002. CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Medium Cutting Mild Steel Carbon Steel·Alloy Steel (180─280HB) Stainless Steel (<200HB) A SMG SMG SMG SRF SRF SRF Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Cutting Conditions : Stable Cutting General Cutting Unstable Cutting P Steel M Stainless Steel WorkMaterialK Cast Iron N Non-Ferrous Metal POSI11º S Heat-resistant Alloy, Titanium Alloy Coated Cermet CoatedCermet Carbide WITH HOLE Shape Order Number (ISO) Number RE (inch) R/L SRF VPET1.51.50.2RSRF VPET080201R-SRF .004 a VPET1.51.50.2LSRF VPET080201L-SRF .004 a VPET1.51.50.5RSRF VPET080202R-SRF .008 a VPET1.51.50.5LSRF VPET080202L-SRF .008 a VPET22V3RSRF VPET1103V3R-SRF .0012 a D010 D014 VPET22V3LSRF VPET1103V3L-SRF .0012 a D015 VPET220.2RSRF VPET110301R-SRF .004 a VPET220.2LSRF VPET110301L-SRF .004 a Finish VPET220.5RSRF VPET110302R-SRF .008 a Cutting VPET220.5LSRF VPET110302L-SRF .008 a SMG VPGT1.51.50.2MSMG VPGT080201M-SMG .004 a VPGT1.51.50.5MSMG VPGT080202M-SMG .008 a D010 VPGT220.2MSMG VPGT110301M-SMG .004 a D014 Medium VPGT220.5MSMG VPGT110302M-SMG .008 a D015 Cutting a = a : USA Stock s : Stocked in Japan A188 <10 inserts in one case> CHIP BREAKER A072