Общий каталог Mitsubishi 2020 - 2021 - страница 1757

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

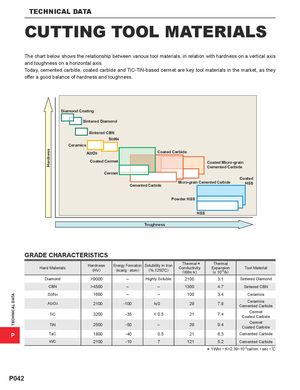

TECHNICAL DATA Hardness TECHNICAL DATA CUTTING TOOL MATERIALS The chart below shows the relationship between various tool materials, in relation with hardness on a vertical axis and toughness on a horizontal axis. Today, cemented carbide, coated carbide and TiC-TiN-based cermet are key tool materials in the market, as they offer a good balance of hardness and toughness. Diamond Coating Sintered Diamond Sintered CBN Ceramics Coated Carbide Coated Cermet Coated Micro-grain Cemented Carbide Cermet Coated Cemented Carbide Micro-grain Cemented Carbide HSS Powder HSS HSS Toughness GRADE CHARACTERISTICS Hard Materials Hardness(HV) Energy Formation Solubility in Iron(kcal/g · atom)(%.1250r)* ThermalConductivity(W/m·k)ThermalExpansion(x 10-6/k)Tool Material Diamond >9000 – Highly Soluble 2100 3.1 Sintered Diamond CBN >4500 – – 1300 4.7 Sintered CBN Si3N4 1600 – – 100 3.4 Ceramics AI2O3 2100 -100 i0 29 7.8 CeramicsCemented Carbide TiC 3200 -35 < 0.5 21 7.4 CermetCoated Carbide TiN 2500 -50 – 29 9.4 CermetCoated Carbide P TaC 1800 -40 0.5 21 6.3 Cemented Carbide WC 2100 -10 7 121 5.2 Cemented Carbide * 1W/m • K=2.39×10-3cal/cm • sec • r P042