Общий каталог Mitsubishi 2020 - 2021 - страница 1433

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

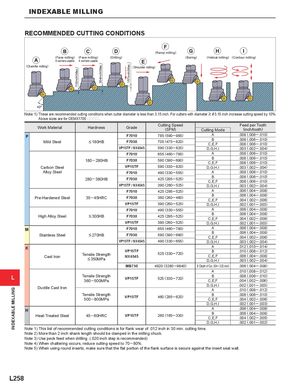

INDEXABLE MILLING .118inch(Max.) .354inch(Max.) .157inch(Max.) INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS (Ramp milling) (Face milling) (Face milling) (Drilling) (Boring) (Helical milling) (Contour milling) 8 corners usable 4 corners usable (Chamfer milling) (Shoulder milling) Note 1) These are recommended cutting conditions when cutter diameter is less than 3.15 inch. For cutters with diameter > &3.15 inch increase cutting speed by 10%. Above sizes are for OEMX1705 pppp. Work Material Hardness Grade Cutting Speed Feed per Tooth(SFM)Cutting Mode(inch/tooth) P Mild Steel F7010 785 (590─985) A .008 (.006─ .010)< 180HBF7030705 (475─820)B.008 (.006─.010)C,E,F.008 (.006─ .010) VP15TF / NX4545 590 (330─820) D,G,H,I .003 (.002─.004) F7010 655 (460─785) A .008 (.006─ .010) 180─ 280HB F7030 590 (390─690) B .008 (.006─.010)C,E,F.008 (.006─ .010) Carbon Steel VP15TF 590 (330─820) D,G,H,I .003 (.002─ .004) Alloy Steel F7010 490 (330─555) A .008 (.006─ .010) 280─ 380HB F7030 425 (295─525) B .008 (.006─.010)C,E,F.008 (.006─ .010) VP15TF / NX4545 390 (260─525) D,G,H,I .003 (.002─.004) F7010 425 (295─525) A .006 (.004─ .008) Pre-Hardened Steel 35─ 45HRC F7030 360 (260─460) B .006 (.004─.008)C,E,F.004 (.002─ .006) VP15TF 390 (260─525) D,G,H,I .002 (.001─ .003) F7010 490 (330─555) A .006 (.004─ .008) High Alloy Steel < 300HB F7030 425 (295─525) B .006 (.004─.008)C,E,F.004 (.002─ .006) VP15TF 390 (260─525) D,G,H,I .002 (.001─ .003) M F7010 655 (460─785)Stainless Steel< 270HBF7030590 (390─690)A .006 (.004─ .008)B.006 (.004─.008)C,E,F.004 (.002─ .006) VP15TF / NX4545 490 (330─655) D,G,H,I .003 (.002─.004) K Cast Iron VP15TFTensile Strength< 350MPaNX4545525 (330─ 720) A .012 (.010─.014)B.010 (.008 ─.012)C,E,F.006 (.004─.008)D,G,H,I.003 (.002─.004) MB730 4920 (3280 ─9840) B (Depth of Cut .004─.020 inch) .006 (.004─.008) A .010 (.008─ .012) L Tensile Strength360─ 500MPa VP15TF 525 (330─720) B .008 (.006─.010)C,E,F.004 (.002─.006) Ductile Cast Iron D,G,H,I .002 (.001─.003)A.010 (.008─.012) Tensile Strength500─ 800MPa VP15TF 460 (295 ─620) B .008 (.006─.010)C,E,F.004 (.002─.006) D,G,H,I .002 (.001─.003) H Heat-Treated Steel 45─ 60HRC VP15TF 260 (165─ 330) A .006 (.004─.008)B.006 (.004 ─.008)C,E,F.004 (.002─.005) D,G,H,I .002 (.001─.002) Note 1) This list of recommended cutting conditions is for flank wear of .012 inch in 30 min. cutting time. Note 2) More than 2 inch shank length should be clamped in the milling chuck. Note 3) Use peck feed when drilling. (.020 inch step is recommended) Note 4) When chattering occurs, reduce cutting speed to 70 ─ 80%. Note 5) When using round inserts, make sure that the flat portion of the flank surface is secure against the insert seat wall. L258