Общий каталог Mitsubishi 2020 - 2021 - страница 1410

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

RMPX

X(inch)

DCX

INDEXABLE MILLING

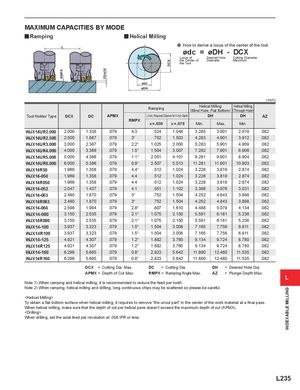

MAXIMUM CAPACITIES BY MODE

y Ramping y Helical Milling

L a How to derive a locus of the center of the tool.

ødc = øDH - DCX

Locus of Desired Hole Cutting Diameter

the Center of Diameter Maximum

the Tool

ødc

øDH

( inch)

Ramping Helical Milling Helical Milling(Blind Hole, Flat Bottom)(Through Hole)

Tool Holder Type DCX DC APMX L (inch) Required Distance for X inch Depth DH DH AZ

RMPX

x = .039 x = .079 Min. Max. Min.

WJX14UR2.000 2.000 1.338 .079 4.3 .524 1.048 3.285 3.901 2.919 .082

WJX14UR2.500 2.500 1.887 .079 3° .752 1.503 4.283 4.901 3.912 .082

WJX14UR3.000 3.000 2.387 .079 2.2° 1.025 2.050 5.283 5.901 4.909 .082

WJX14UR4.000 4.000 3.386 .079 1.5° 1.504 3.007 7.282 7.901 6.906 .082

WJX14UR5.000 5.000 4.386 .079 1.1° 2.051 4.101 9.281 9.901 8.904 .082

WJX14UR6.000 6.000 5.386 .079 0.9° 2.507 5.013 11.281 11.901 10.903 .082

WJX14R50 1.969 1.358 .079 4.4° .512 1.024 3.228 3.819 2.874 .082

WJX14-050 1.969 1.358 .079 4.4 .512 1.024 3.228 3.819 2.874 .082

WJX14R050 1.969 1.358 .079 4.4 .512 1.024 3.228 3.819 2.874 .082

WJX14-052 2.047 1.437 .079 4.1 .551 1.102 3.386 3.976 3.031 .082

WJX14-063 2.480 1.870 .079 3° .752 1.504 4.252 4.843 3.898 .082

WJX14R063 2.480 1.870 .079 3° .752 1.504 4.252 4.843 3.898 .082

WJX14-066 2.598 1.984 .079 2.8° .807 1.610 4.488 5.079 4.134 .082

WJX14-080 3.150 2.535 .079 2.1° 1.075 2.150 5.591 6.181 5.236 .082

WJX14R080 3.150 2.535 .079 2.1° 1.075 2.150 5.591 6.181 5.236 .082

WJX14-100 3.937 3.323 .079 1.5° 1.504 3.008 7.165 7.756 6.811 .082

WJX14R100 3.937 3.323 .079 1.5° 1.504 3.008 7.165 7.756 6.811 .082

WJX14-125 4.921 4.307 .079 1.2° 1.882 3.760 9.134 9.724 8.780 .082

WJX14R125 4.921 4.307 .079 1.2° 1.882 3.760 9.134 9.724 8.780 .082

WJX14-160 6.299 5.685 .079 0.8° 2.823 5.642 11.890 12.480 11.535 .082

WJX14R160 6.299 5.685 .079 0.8° 2.823 5.642 11.890 12.480 11.535 .082

DCX = Cutting Dia. Max. DC = Cutting Dia. DH = Desired Hole Dia.

APMX = Depth of Cut Max. RMPX = Ramping Angle Max. AZ = Plunge Depth Max.

L

Note 1) When ramping and helical milling, it is recommended to reduce the feed per tooth.

Note 2) When ramping, helical milling and drilling, long continuous chips may be scattered so please be careful.