Общий каталог Mitsubishi 2020 - 2021 - страница 1407

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

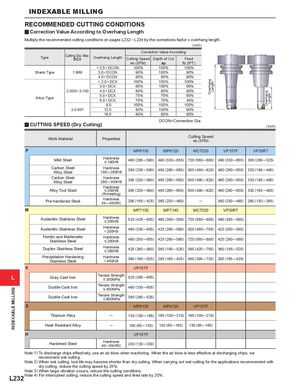

INDEXABLE MILLING Overhang Length Overhang Length INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS y Correction Value According to Overhang Length Multiply the recommended cutting conditions on pages L232 ─ L234 by the corrections factor x overhang length. ( inch) Correction Value According Type Cutting Dia. Max.DCXOverhang Length Cutting Speed Depth of Cut Feed vc (SFM) ap fz (IPT) < 2.5 × DCON 100% 100% 100% Shank Type 1.969 3.0 × DCON 90% 100% 90% 4.0 × DCON 80% 80% 90% < 2.5 × DCX 100% 100% 100% 3.0 × DCX 85% 100% 90% 2.000─ 3.150 4.0 × DCX 80% 80% 80% Arbor Type 5.0 × DCX 75% 75% 60%6.0 × DCX70%70%40% 8.0 100% 100% 100% > 3.937 12.0 85% 100% 90% 16.0 80% 80% 80% DCON=Connection Dia. y CUTTING SPEED (Dry Cutting) ( inch) Work Material Properties Cutting Speedvc (SFM) P MP6130 MP6120 MC7020 VP15TF VP30RT Mild Steel Hardness< 180HB 460 (295 ─ 590) 490 (330 ─ 655) 720 (560 ─ 885) 490 (330 ─ 655) 395 (260 ─ 525) Carbon SteelAlloy Steel Hardness180 ─ 280HB395 (230 ─ 590)460 (260 ─ 655) 655 (490 ─ 820) 460 (260 ─ 655) 330 (195 ─ 490) Carbon SteelAlloy Steel Hardness280 ─ 350HB395 (230 ─ 590)460 (260 ─ 655) 655 (490 ─ 820) 460 (260 ─ 655) 330 (195 ─ 490) Hardness Alloy Tool Steel < 350HB 395 (230 ─ 590) 460 (260 ─ 655) 655 (490 ─ 820) 460 (260 ─ 655) 330 (195 ─ 490) (Annealing) Pre-hardened Steel Hardness35 ─ 45HRC295 (165 ─ 425)360 (230 ─ 490) ─ 360 (230 ─ 490) 260 (130 ─ 395) M MP7130 MP7140 MC7020 VP30RT Austenitic Stainless Steel Hardness< 200HB 525 (425 ─ 655) 490 (395 ─ 590) 720 (560 ─ 885) 490 (395 ─ 590) Austenitic Stainless Steel Hardness> 200HB 460 (330 ─ 655) 425 (260 ─ 590) 620 (460 ─ 785) 425 (260 ─ 590) Ferritic and MartensiticStainless SteelHardness< 200HB490 (330 ─ 655) 425 (260 ─ 590) 720 (560 ─ 885) 425 (260 ─ 590) Duplex Stainless Steel Hardness< 280HB 425 (260 ─ 590) 360 (195 ─ 525) 590 (425 ─ 755) 360 (195 ─ 525) Precipitation HardeningStainless SteelHardness< 450HB360 (195 ─ 525) 295 (165 ─ 425) 560 (395 ─ 720) 295 (165 ─ 425) K VP15TF L Gray Cast Iron Tensile Strength< 350MPa525 (395 ─ 655) Ductile Cast Iron Tensile Strength< 450MPa490 (330 ─ 655) Ductile Cast Iron Tensile Strength< 800MPa395 (260 ─ 525) S MP9130 MP9120 VP15TF Titanium Alloy ─ 130 (100 ─ 195) 165 (100 ─ 210) 165 (100 ─ 210) Heat Resistant Alloy ─ 100 (65 ─ 130) 130 (65 ─ 165) 130 (65 ─ 165) H VP15TF Hardened Steel Hardness40 ─ 55HRC230 (130 ─ 330) Note 1) To discharge chips effectively, use an air blow when machining. When the air blow is less effective at discharging chips, we recommend wet cutting. Note 2) When wet cutting, tool life may become shorter than dry cutting. When carrying out wet cutting for the applications recommended with dry cutting, reduce the cutting speed by 25%. Note 3) When large vibration occurs, reduce the cutting conditions. L232 Note 4) For interrupted cutting, reduce the cutting speed and feed rate by 20%.