Общий каталог Mitsubishi 2020 - 2021 - страница 1403

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

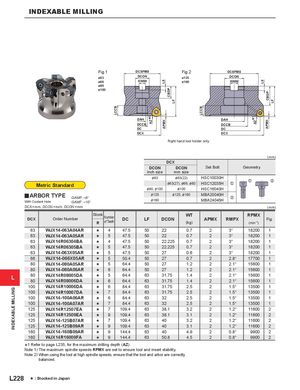

INDEXABLE MILLING LCCB 1*AZ L8APMX CBDP LF LCCB 1* AZ L8 CBDPAPMX LF INDEXABLE MILLING Fig.1 DCSFMS Fig.2 DCSFMS ø63 DCON ø125 DCON ø66 KWW ø160 KWW ø80 ø100 DAH DAH DCCB DCCB DC DC DCX DCX Right hand tool holder only. ( mm) DCX DCON DCON Set Bolt Geometry inch size mm size &63 &63(22) HSC10030H z x Metric Standard &63(27), &66, &80 HSC12035H z &80, &100 &100 HSC16040H y ARBOR TYPE GAMP: ‒6°With Coolant HoleGAMF : ‒10° &125 &125, &160 MBA20040H x&160MBA24045H DCX = mm, DCON = inch, DCON = mm ( mm) DCX Order Number Stock NumberRof Teeth DC WT RPMXLFDCONAPMXRMPXFig.(kg)(min-1) 63 WJX14-063A04AR s 4 47.5 50 22 0.7 2 3° 18200 1 63 WJX14-063A05AR s 5 47.5 50 22 0.7 2 3° 18200 1 63 WJX14R06304BA s 4 47.5 50 22.225 0.7 2 3° 18200 1 63 WJX14R06305BA s 5 47.5 50 22.225 0.7 2 3° 18200 1 63 WJX14-063X05AR s 5 47.5 50 27 0.6 2 3° 18200 1 66 WJX14-066X05AR s 5 50.4 50 27 0.7 2 2.8° 17700 1 80 WJX14-080A05AR s 5 64.4 50 27 1.2 2 2.1° 15600 1 80 WJX14-080A06AR s 6 64.4 50 27 1.2 2 2.1° 15600 1 L 80 WJX14R08005DA s 5 64.4 63 31.75 1.480WJX14R08006DAs664.46331.751.4222.1°15600 12.1°156001 100 WJX14R10006DA s 6 84.4 63 31.75 2.5 2 1.5° 13500 1 100 WJX14R10007DA s 7 84.4 63 31.75 2.5 2 1.5° 13500 1 100 WJX14-100A06AR s 6 84.4 63 32 2.5 2 1.5° 13500 1 100 WJX14-100A07AR s 7 84.4 63 32 2.5 2 1.5° 13500 1 125 WJX14R12507EA s 7 109.4 63 38.1 3.2 2 1.2° 11600 2 125 WJX14R12509EA s 9 109.4 63 38.1 3.1 2 1.2° 11600 2 125 WJX14-125B07AR s 7 109.4 63 40 3.2 2 1.2° 11600 2 125 WJX14-125B09AR s 9 109.4 63 40 3.1 2 1.2° 11600 2 160 WJX14-160B09AR s 9 144.4 63 40 4.9 2 0.8° 9900 2 160 WJX14R16009FA s 9 144.4 63 50.8 4.5 2 0.8° 9900 2 *1 Refer to Note 1) The page L235, for the maximum spindle maximum drilling depth (AZ). speeds RPMX are set to ensure tool and insert stability. Note 2) When using the tool at high spindle speeds, ensure that the tool and arbor are correctly balanced. L228 s : Stocked in Japan