Общий каталог Mitsubishi 2020 - 2021 - страница 1364

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

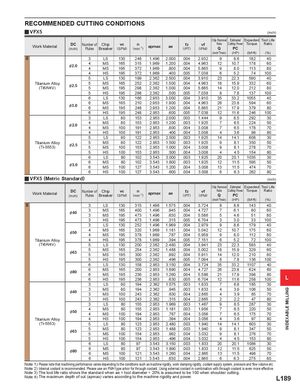

RECOMMENDED CUTTING CONDITIONS y VFX5 (inch) Chip Removal Estimated Expected Tool Life Work Material DC Number of Chip vc(inch)FlutesBreaker(SFM)n(min-1)apmaxaefz vf(IPT)(IPM)Rate Cutting Power Torque RatioQPC (inch3/min) (HP) (lbf-ft) (%) S 3 LS 130 248 1.496 2.000 .004 2.932 9 8.6 182 40 &2.0 44 MS 165 315 1.969 1.200 .004 4.963 12 10.7 178 60MS1953721.969.800.0045.86598.011380 4 HS 195 372 1.969 .400 .005 7.038 6 5.2 74 100 5 LS 130 199 2.362 2.500 .004 3.910 23 22.3 590 40 Titanium Alloy(Ti6Al4V)&2.5 55 MS 165 252 2.362 1.500 .004 4.963 18 15.9 332 60MS1952982.3621.000.0045.8651412.021280 5 HS 195 298 2.362 .500 .005 7.038 8 7.8 137 100 6 LS 130 166 2.953 3.000 .004 3.910 35 33.2 1055 40 &3.0 66 MS 165 210 2.953 1.800 .004 4.963 26 23.8 594 60MS1952482.9531.200.0045.8652117.937980 6 HS 195 248 2.953 .600 .005 7.038 12 11.6 246 100 3 LS 80 153 2.953 2.000 .003 1.444 9 8.5 292 30 &2.0 44 MS 80 153 2.953 1.200 .003 1.925MS1001912.953.800.0043.008776.5 224 506.517870 4 HS 100 191 2.953 .400 .004 3.008 4 3.6 98 80 5 LS 80 122 2.953 2.500 .003 1.925 14 14.1 608 30 Titanium Alloy(Ti-5553)&2.5 55 MS 80 122 2.953 1.500 .003 1.925MS1001532.9531.000.0043.008998.1350 508.127870 5 HS 100 153 2.953 .500 .004 3.008 4 4.5 154 80 6 LS 80 102 3.543 3.000 .003 1.925 20 20.1 1035 30 &3.0 66 MS 80 102 3.543 1.800 .003 1.925 12 11.5 595 50MS1001273.5431.200.0043.0081311.547470 6 HS 100 127 3.543 .600 .004 3.008 6 6.3 262 80 y VFX5 (Metric Standard) (inch) Chip Removal Estimated Expected Tool Life Work Material DC Number of Chip vc(inch)FlutesBreaker(SFM)n(min-1)apmaxaefz vf(IPT)(IPM)Rate Cutting Power Torque RatioQPC (inch3/min) (HP) (lbf-ft) (%) S 3 LS 130 315 1.496 1.575 .004 3.724 9 8.6 143 40 &40 33 MS 165 400 1.496 .945 .004 4.727MS1954731.496.630.0045.586756.14.680 605180 3 HS 195 473 1.496 .315 .005 6.704 3 3.0 33 100 3 LS 130 252 1.496 1.969 .004 2.979 9 8.6 179 40 &50 44 MS 165 320 1.969 1.181 .004 5.042 12 10.7 175 60MS1953781.969.787.0045.95998.011280 Titanium Alloy 4 HS 195 378 1.969 .394 .005 7.151 6 5.2 72 100 (Ti6Al4V) 5 LS 130 200 2.362 2.480 .004 3.941 23 22.3 585 40 &63 55 MS 165 254 2.362 1.488 .004 5.002 18 15.9 329 60MS1953002.362.992.0045.9111412.021080 5 HS 195 300 2.362 .496 .005 7.094 8 7.8 136 100 6 LS 130 158 2.953 3.150 .004 3.724 35 33.2 1107 40 &80 66 MS 165 200 2.953 1.890 .004 4.727 26 23.8 624 60MS1952362.9531.260.0045.5862117.9398806HS1952362.953.630.0056.7041211.6258100L 3 LS 80 194 2.362 1.575 .003 1.833 7 6.8 185 30 &40 33 MS 80 194 2.362 .945 .003 1.833MS1002432.362.630.0042.865443.9 106 503.98570 3 HS 100 243 2.362 .315 .004 2.865 2 2.2 47 80 3 LS 80 155 2.953 1.969 .003 1.467 9 8.5 287 30 &50 44 MS 80 155 2.953 1.181 .003 1.956MS1001942.953.787.0043.056776.5 220 506.517570 Titanium Alloy 4 HS 100 194 2.953 .394 .004 3.056 4 3.6 97 80 (Ti-5553) 5 LS 80 123 2.953 2.480 .003 1.940 14 14.1 603 30 &63 55 MS 80 123 2.953 1.488 .003 1.940MS1001542.953.992.0043.032998.1 347 508.127670 5 HS 100 154 2.953 .496 .004 3.032 4 4.5 153 80 6 LS 80 97 3.543 3.150 .003 1.833 20 20.1 1086 30 &80 66 MS 80 97 3.543 1.890 .003 1.833 12 11.5 625 50MS1001213.5431.260.0042.8651311.549870 6 HS 100 121 3.543 .630 .004 2.865 6 6.3 275 80 Note 1) Please note that machining performance varies depending to the conditions such as machine rigidity, work clamping rigidity, coolant supply system, pressure and flow volume etc. Note 2) Internal coolant is recommended. Please use an FMH type arbor for through coolant. Using external coolant in combination with through coolant is even more effective. Note 3) The tool life ratio shows the standard when ae = tool diameter × 20% is assumed to be 100 when shoulder cutting. Note 4) The maximum depth of cut (apmax) varies according to the machine rigidity and power. L189 INDEXABLE MILLING