Общий каталог Mitsubishi 2020 - 2021 - страница 1354

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

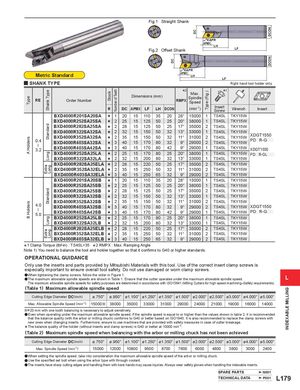

TypeA HoldersB Holders ── Shank TypeStandardLongExtraLongStandardLongExtraLong Stock Number of Teeth DC DC Type (Fig.) DCONDCON INDEXABLE MILLING Fig.1 Straight Shank KAPR APMX LH Fig.2 Offset Shank LF KAPR Metric Standard APMX LH LF y SHANK TYPE Right hand tool holder only. RE Order Number Dimensions (mm) *2 Max.RMPXSpindleSpeed *1 R DC APMX LF LH DCON (min-1) InsertScrewWrench Insert BXD4000R201SA20SA s 1 20 15 110 35 20 28° 15000 1 TS4SL TKY15W BXD4000R252SA25SA s 2 25 15 125 50 25 20° 38000 1 TS4SL TKY15W BXD4000R282SA25SA s 2 28 15 125 50 25 17° 35000 2 TS4SL TKY15W 0.4 BXD4000R322SA32SABXD4000R352SA32SABXD4000R403SA32SAs2 32s235s34015150 501515050151708032323213°33000 1 TS4SL TKY15W11°3100029°290002TS4SLTS4SLTKY15WTKY15WXDGT1550PDpR-Gpp 3.2 BXD4000R403SA42SA s 3 40 15 170 80 42 9° 29000 1 TS4SL TKY15W XDGT1550 BXD4000R252SA25LA s 2 25 15 170 80 25 20° 38000 1 TS4SL TKY15W PDpR-GLpp BXD4000R322SA32LA s 2 32 15 200 80 32 13° 33000 1 TS4SL TKY15W BXD4000R282SA25ELA s 2 28 15 220 50 25 17° 35000 2 TS4SL TKY15W BXD4000R352SA32ELA s 2 35 15 250 50 32 11° 31000 2 TS4SL TKY15W BXD4000R403SA32ELA s 3 40 15 250 65 32 9° 29000 2 TS4SL TKY15W BXD4000R201SA20SB s 1 20 15 110 35 20 28° 15000 1 TS4SL TKY15W BXD4000R252SA25SB s 2 25 15 125 50 25 20° 38000 1 TS4SL TKY15W BXD4000R282SA25SB s 2 28 15 125 50 25 17° 35000 2 TS4SL TKY15W BXD4000R322SA32SB s 2 32 15 150 50 32 13° 33000 1 TS4SL TKY15W BXD4000R352SA32SB s 2 35 15 150 50 32 11° 31000 2 TS4SL TKY15W 4.0 BXD4000R403SA32SB s 3 40 15 170 80 32 9° 29000 2 TS4SL TKY15W XDGT1550 5.0 BXD4000R403SA42SB s 3 40 15 170 80 42 9° 29000 1 TS4SL TKY15W PDpR-Gpp BXD4000R252SA25LB s 2 25 15 170 80 25 20° 38000 1 TS4SL TKY15W BXD4000R322SA32LB s 2 32 15 200 80 32 13° 33000 1 TS4SL TKY15W BXD4000R282SA25ELB s 2 28 15 220 50 25 17° 35000 2 TS4SL TKY15W BXD4000R352SA32ELB s 2 35 15 250 50 32 11° 31000 2 TS4SL TKY15W BXD4000R403SA32ELB s 3 40 15 250 65 32 9° 29000 2 TS4SL TKY15W *1 Clamp Torque Note 1) You need * (lbf-in) : TS4SL=35 2 RMPX : Max. Ramping Angle to balance the tool and holder together so that it confirms to G40 or higher standards. OPERATIONAL GUIDANCE Only use the inserts and parts provided by Mitsubishi Materials with this tool. Use of the correct insert clamp screws is especially important to ensure overall tool safety. Do not use damaged or worn clamp screws. aWhen tightening the clamp screws, follow the order in Figure 1.aThe maximum allowable spindle speeds are shown in Table 1. Ensure that the cutter operates under the maximum allowable spindle speed. L The maximum allowable spindle speeds for safety purposes are determined in accordance with ISO15641 (Milling Cutters for high speed machining–Safety requirements). (Table 1) Maximum allowable spindle speed Cutting Edge Diameter DC(inch) ø.750" ø.950" ø1.100" ø1.250" ø1.350" ø1.500" ø2.000" ø2.500" ø3.000" ø4.000" ø5.000" Max. Allowable Spindle Speed (min-1) 15000 38000 35000 33000 31000 29000 24000 21000 19000 16000 14000 ø 20 mm with one tooth balancing is necessary to adjust sensitively. aEven when operating under the maximum allowable spindle speed, if the spindle speed is equal to or higher than the values shown in table 2, it is recommended that the balance quality (with the arbor or milling chuck) conforms to G40 or better based on ISO1940. It is also recommended to replace the clamp screws with new ones when changing inserts. Furthermore, ensure to use machines that are provided with safety measures in case of cutter breakage. * The balance quality of the holder (without inserts and (Table 2) Maximum spindle speed when clamp screws) balancing is G40 or better at 10000 min-1. with the arbor or milling chuck has not been achieved Cutting Edge Diameter DC(inch) ø.750" ø.950" ø1.100" ø1.250" ø1.350" ø1.500" ø2.000" ø2.500" ø3.000" ø4.000" ø5.000" Max. Spindle Speed (min-1) 15000 12000 10800 9500 8700 7600 6000 4800 3800 3000 2400 aWhen setting the spindle speed, take into consideration the maximum allowable spindle speed of the arbor or milling chuck. aUse the specified set bolt when using the arbor type with through coolant. aThe inserts have sharp cutting edges and handling them with bare hands may cause injuries. Always wear safety gloves when handling the indexable inserts. SPARE PARTS N001 TECHNICAL DATA P001 L179