Общий каталог Mitsubishi 2020 - 2021 - страница 1352

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

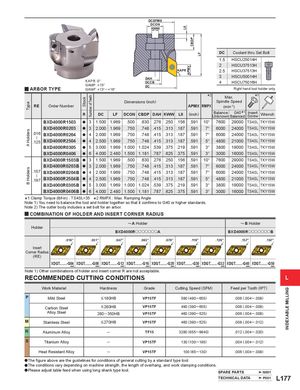

TypeA HoldersB Holders ── Stock Number of Teeth L8 APMX CBDP LF INDEXABLE MILLING DCSFMS DCON KWW DC Coolant thru Set Bolt 1.5 HSCU25014H 2 HSCU37513H KAPR 2.5 HSCU37513H KAPR :0° DAHDCCB 3 HSCU50014H4HSCU75016H GAMP :+15°y ARBOR TYPEGAMF :+13°─ +16° DC Right hand tool holder only. *2 Max. *1 Dimensions (inch) Spindle Speed RE Order Number APMX RMPX (min-1) R DC LF DCON CBDP DAH KWW L8 (inch) Balance Unknown BaGla4n0ce*d1 InsertScrewWrench BXD4000R1503 a 3 1.500 1.969 .500 .630 .276 .250 .156 .591 10° 7600 29000 TS4SL TKY15W BXD4000R0203 a 3 2.000 1.969 .750 .748 .415 .313 .187 .591 7° 6000 24000 TS4SL TKY15W .016 BXD4000R0204 a 4 2.000 1.969 .750 .748 .415 .313 .187 .591 7° 6000 24000 TS4SL TKY15W .125 BXD4000R2504 a 4 2.500 1.969 .750 .748 .415 .313 .187 .591 5° 4800 21000 TS4SL TKY15W BXD4000R0305 a 5 3.000 1.969 1.000 1.024 .539 .375 .219 .591 3° 3800 19000 TS4SL TKY15W BXD4000R0406 a 6 4.000 2.480 1.500 1.181 .787 .625 .375 .591 3° 3000 16000 TS4SL TKY15W BXD4000R1503B a 3 1.500 1.969 .500 .630 .276 .250 .156 .591 10° 7600 29000 TS4SL TKY15W BXD4000R0203B a 3 2.000 1.969 .750 .748 .415 .313 .187 .591 7° 6000 24000 TS4SL TKY15W .157 BXD4000R0204B a 4 2.000 1.969 .750 .748 .415 .313 .187 .591 7° 6000 24000 TS4SL TKY15W .197 BXD4000R2504B a 4 2.500 1.969 .750 .748 .415 .313 .187 .591 5° 4800 21000 TS4SL TKY15W BXD4000R0305B a 5 3.000 1.969 1.000 1.024 .539 .375 .219 .591 3° 3800 19000 TS4SL TKY15W BXD4000R0406B a 6 4.000 2.480 1.500 1.181 .787 .625 .375 .591 3° 3000 16000 TS4SL TKY15W *1 Clamp Torque Note 1) You need * (lbf-in) : TS4SL=35 2 RMPX : Max. Ramping Angle to balance the tool and holder together so that it confirms to G40 or higher standards. Note 2) The cutter body includes a set bolt for an arbor. y COMBINATION OF HOLDER AND INSERT CORNER RADIUS ~ A Holder ~ B Holder Holder BXD4000RoooooooA BXD4000RoooooooB .016" .031" .047" .063" .079" .118" .126" .157" .197" Insert Corner Radius (RE) XDGT........-G04 XDGT........-G08 XDGT........-G12 XDGT........-G16 XDGT........-G20 XDGT........-G30 XDGT........-G32 XDGT........-G40 XDGT........-G50 Note 1) Other combinations of holder and insert corner R are not acceptable. RECOMMENDED CUTTING CONDITIONS L Work Material Hardness Grade Cutting Speed (SFM) Feed per Tooth (IPT) P Mild Steel < 180HB VP15TF 590 (490─655) .006 (.004─.008) Carbon Steel < 280HB VP15TF 490 (390─655) .006 (.004─.008) Alloy Steel 280─ 350HB VP15TF 460 (390─525) .006 (.004─.008) M Stainless Steel < 270HB VP15TF 460 (390─525) .008 (.004─.012) N Aluminum Alloy ─ TF15 3280 (655─9840) .012 (.004─ .020) S Titanium Alloy ─ VP15TF 130 (100─195) .004 (.004─.012) Heat Resistant Alloy ─ VP15TF 100 (65─130) .006 (.004─.008) aThe figure above are the guidelines for conditions of general cutting by a standard type tool. aThe conditions vary depending on machine strength, the length of overhang, and work clamping conditions. aPlease adjust table feed when using long shank type tool. SPARE PARTS N001 TECHNICAL DATA P001 L177