Общий каталог Mitsubishi 2020 - 2021 - страница 1348

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

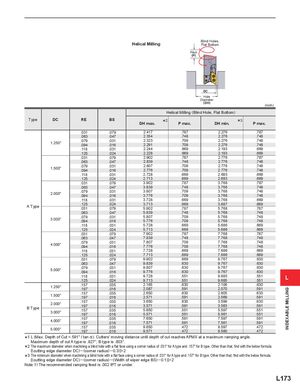

Helical Milling Blind Holes,Flat Bottom Pitch (P) DC Hole Diameter (DH) (inch) Helical Milling (Blind Hole, Flat Bottom) Type DC RE BS DH max. *2 P max. DH min. *3 P max. .031 .079 2.417 .787 2.276 .787 .063 .047 2.354 .748 2.276 .748 1.250" .079.094 .031.016 2.3232.291 .709.709 2.276 .7482.276.748 .118 .031 2.244 .669 2.193 .669 .125 .024 2.228 .669 2.193 .669 .031 .079 2.902 .787 2.776 .787 .063 .047 2.839 .748 2.776 .748 1.500" .079.094 .031.016 2.8072.776 .709.709 2.776 .7482.776.748 .118 .031 2.728 .669 2.693 .669 .125 .024 2.713 .669 2.693 .669 .031 .079 3.902 .787 3.768 .787 .063 .047 3.839 .748 3.768 .748 2.000" .079.094 .031.016 3.8073.776 .709.709 3.768 .7483.768.748 .118 .031 3.728 .669 3.768 .669 A Type .125 .024 3.713 .669 3.687 .669.031.0795.902.7875.768.787 .063 .047 5.839 .748 5.768 .748 3.000" .079.094 .031.016 5.8075.776 .709.709 5.768 .7485.768.748 .118 .031 5.728 .669 5.686 .669 .125 .024 5.713 .669 5.686 .669 .031 .079 7.902 .787 7.768 .787 .063 .047 7.839 .748 7.768 .748 4.000" .079.094 .031.016 7.8077.776 .709.709 7.768 .7487.768.748 .118 .031 7.728 .669 7.686 .669 .125 .024 7.713 .669 7.686 .669 .031 .079 9.902 .669 9.767 .630 .063 .047 9.839 .630 9.767 .630 5.000" .079.094 .031.016 9.8079.776 .630.630 9.767 .6309.767.630 .118 .031 9.728 .551.125.0249.713.551 9.6859.685 .551.551 L 1.250" .157.197 .035.016 2.1652.087 .630.591 2.106 .6302.070.591 1.500" .157.197 .035.016 2.6502.571 .630.591 2.605 .6302.569.591 2.000"B Type3.000".157.197.157.197.035.016.035.016 3.6503.5715.6505.571.630.591.551.551 3.599 .6303.563.5915.597.5515.561.551 4.000" .157.197 .035.016 7.6507.571 .591.591 7.597 .5917.561.591 5.000" .157.197 .035.016 9.6509.571 .472.472 9.597 .4729.560.472 *1 L (Max. Depth of Cut =.591" / Maximum depth of cut A type tan %). Cutters' is .827", B type moving distance is .803". until depth of cut reaches APMX at a maximum ramping angle. *2 The maximum diameter when {(cutting edge diameter machining a blind hole with a flat face DC)─(corner radius)─0.3)}×2 using a corner radius of .031" for A type and .157" for B type. Other than that, find with the below formula. *3 The minimum diameter when {(cutting edge diameter machining a blind DC)─(corner hole with a radius)─ flat face (Width using a corner radius of .031" for A of wiper edge BS)─0.1)}×2 type and .157" for B type. Other than that, find with the below formula. Note 1) The recommended ramping feed is .002 IPT or under. L173 INDEXABLE MILLING