Общий каталог Mitsubishi 2020 - 2021 - страница 1336

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

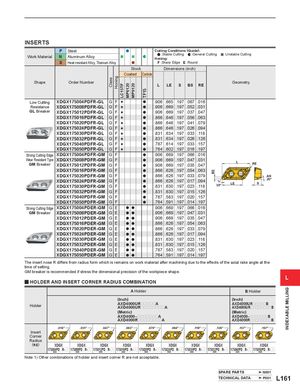

Class Honing LC15TF MP6120 MP9120 TF15 BS INDEXABLE MILLING INSERTS P Steel Cutting Conditions (Guide): Work Material N Aluminum Alloy :Stable Cutting :General Cutting :Unstable CuttingHoning: S Heat-resistant Alloy, Titanium Alloy F :Sharp Edge E :Round Stock Dimensions (inch) Coated Carbide Shape Order Number L LE S BS RE Geometry Low Cutting XDGX175004PDFR-GL G F s a .906 .665 .197 .067 .016 Resistance XDGX175008PDFR-GL G F s a .906 .669 .197 .052 .031 GL Breaker XDGX175012PDFR-GL G F s a .906 .669 .197 .037 .047 XDGX175016PDFR-GL G F s a .866 .646 .197 .056 .063 XDGX175020PDFR-GL G F s a .866 .646 .197 .041 .079 XDGX175024PDFR-GL G F s a .866 .646 .197 .026 .094 XDGX175030PDFR-GL G F s a .831 .634 .197 .033 .118 XDGX175032PDFR-GL G F s a .831 .634 .197 .026 .126 XDGX175040PDFR-GL G F s a .787 .614 .197 .033 .157 XDGX175050PDFR-GL G F s a .764 .602 .197 .016 .197 Strong Cutting Edge XDGX175004PDFR-GM G F a .906 .669 .197 .066 .016 Wear Resistant Type XDGX175008PDFR-GM G F a .906 .669 .197 .047 .031GM BreakerXDGX175012PDFR-GMGFa.906.669.197.035.047LRE XDGX175016PDFR-GM G F a .866 .626 .197 .054 .063 XDGX175020PDFR-GM G F a .866 .626 .197 .033 .079 AN XDGX175024PDFR-GM G FXDGX175030PDFR-GMGF a .866 .626 .197 .017 .094a.831.630.197.023.11830°LE 20°S XDGX175032PDFR-GM G F a .831 .630 .197 .015 .126 XDGX175040PDFR-GM G F a .787 .583 .197 .020 .157 XDGX175050PDFR-GM G F a .764 .591 .197 .014 .197 Strong Cutting Edge XDGX175004PDER-GM G E a a .906 .669 .197 .066 .016 GM Breaker XDGX175008PDER-GM G E a a .906 .669 .197 .047 .031 XDGX175012PDER-GM G E a a .906 .669 .197 .035 .047 XDGX175016PDER-GM G E a a .866 .626 .197 .054 .063 XDGX175020PDER-GM G E a a .866 .626 .197 .033 .079 XDGX175024PDER-GM G E a a .866 .626 .197 .017 .094 XDGX175030PDER-GM G E a a .831 .630 .197 .023 .118 XDGX175032PDER-GM G E a a .831 .630 .197 .015 .126 XDGX175040PDER-GM G E a a .787 .583 .197 .020 .157 XDGX175050PDER-GM G E a a .764 .591 .197 .014 .197 The insert nose R differs from radius form which is remains on work material after machining due to the effects of the axial rake angle at the time of setting. GM breaker is recommended if stress the dimensional precision of the workpiece shape. L y HOLDER AND INSERT CORNER RADIUS COMBINATION A Holder B Holder (Inch) (Inch) Holder AXD4000URpppppA AXD4000URpppppBAXD4000URppppppppAAXD4000URppppppppB (Metric) (Metric) AXD4000–pppppppA AXD4000–pppppppB AXD4000RppppppppA AXD4000RppppppppB .016" .031" .047" .063" .079" .094" .118" .126" .157" .197" Insert Corner Radius (RE) XDGX XDGX XDGX XDGX XDGX XDGX XDGX XDGX XDGX XDGX 175004PDpR-pp 175008PDpR-pp 175012PDpR-pp 175016PDpR-pp 175020PDpR-pp 175024PDpR-pp 175030PDpR-pp 175032PDpR-pp 175040PDpR-pp 175050PDpR-pp Note 1) Other combinations of holder and insert corner R are not acceptable. SPARE PARTS N001 TECHNICAL DATA P001 L161