Общий каталог Mitsubishi 2020 - 2021 - страница 1334

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

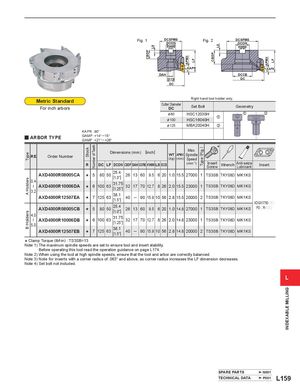

TypeA HoldersB Holders ── Stock Number of Teeth CBDP L8 APMX LF Type (Fig.) CBDP L8 APMX LF INDEXABLE MILLING Fig. 1 DCSFMS Fig. 2 DCSFMS DCON DCON KWW KWW KAPR KAPR DAH DCCB DCCB DC DC Metric StandardFor inch arbors Right hand tool holder only.Cutter DiameterDCSet BoltGeometry & 80 HSC12035H z x z & 100 HSC16040H & 125 MBA20040H x KAPR :90° y ARBOR TYPE GAMP :+14°─ 15°GAMF :+21°─ +26° RE Order Number Dimensions (mm) [inch] Max.WTAPMXSpindle *(kg)(mm)Speed R DC LF DCON CBDP DAH DCSFMS KWW L8 DCCB (min-1) InsertScrewWrench Anti-seize Lubricant Insert AXD4000R08005CA s 5 80 50 25.4[1.0"]2613 60 9.5 6 20 1.0 15.5 27000 1 TS3SB TKY08D MK1KS 0.4 AXD4000R10006DA3.2 s 6 100 63 31.75[1.25"]321770 12.7 8 26 2.0 15.5 23000 1 TS3SB TKY08D MK1KS AXD4000R12507EA s 7 125 63 38.1[1.5"]40─ 90 15.9 10 56 2.8 15.5 20000 2 TS3SB TKY08D MK1KS XDGX1750pp AXD4000R08005CB s 5 80 50 25.4[1.0"]2613 60 9.5 6 20 1.0 14.8 27000 1 TS3SB TKY08D MK1KS PDpR-pp 4.0 AXD4000R10006DB5.0 s 6 100 63 31.75[1.25"]321770 12.7 8 26 2.0 14.8 23000 1 TS3SB TKY08D MK1KS AXD4000R12507EB s 7 125 63 38.1[1.5"]40─ 90 15.9 10 56 2.8 14.8 20000 2 TS3SB TKY08D MK1KS * Clamp Torque (lbf-in) : TS3SB=13 Note 1) The maximum spindle speeds are set to ensure tool and insert stability. Before operating this tool read the operation guidance on page L174. Note 2) When using the tool at high spindle speeds, ensure that the tool and arbor are correctly balanced. Note 3) Note for inserts with a corner radius of .063" and above, as corner radius increases the LF dimension decreases. Note 4) Set bolt not included. L SPARE PARTS N001 TECHNICAL DATA P001 L159