Общий каталог Mitsubishi 2020 - 2021 - страница 1295

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

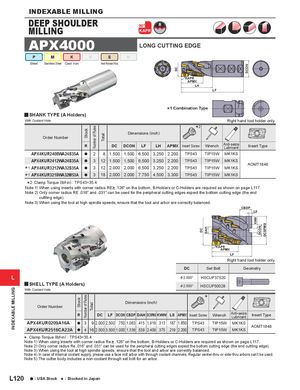

INDEXABLE MILLING Stock StockNumber of Flutes Number of FlutesTotal Total DC DC DAH DCON KWW DCON DCSFMS INDEXABLE MILLING DEEP SHOULDER 90° MILLING KAPR APX4000 LONG CUTTING EDGE P M K N S H Steel Stainless Steel Cast Iron Heat Resistant Alloy KAPR APMX LH LF *1 Combination Type y SHANK TYPE (A Holders) With Coolant Hole Right hand tool holder only. *2 Dimensions (inch) Order Number R DC DCON LF LH APMX Insert Screw Wrench Anti-seizeLubricantInsert Type APX4KUR2408WA24S35A a 2 8 1.500 1.500 6.500 3.250 2.200 TPS43 TIP15W MK1KS APX4KUR2412WA24S35A a 3 12 1.500 1.500 6.500 3.250 2.200 TPS43 TIP15W MK1KS AOMT1848 *1 APX4KUR3212WA32S35A a 3 12 2.000 2.000 6.500 3.250 2.200 TPS43 TIP15W MK1KS *1 APX4KUR3218WA32M53A a 3 18 2.000 2.000 7.750 4.500 3.300 TPS43 TIP15W MK1KS *2 Note Clamp Torque (lbf-in) : 1) When using inserts TPS43=35.4 with corner radius RE>.126" on the bottom, B-Holders or C-Holders are required as shown on page L117. Note 2) Only corner radius RE .016" and .031" can be used for the peripheral cutting edges expect the bottom cutting edge (the end cuttting edge). Note 3) When using the tool at high spindle speeds, ensure that the tool and arbor are correctly balanced. CBDP L8 KAPR APMX LF Right hand tool holder only. DC Set Bolt Geometry L & 2.000" HSCUF37520 y SHELL TYPE (A Holders) & 2.500" HSCUF50028 With Coolant Hole * Dimensions (inch) Order Number R DC LF DCON CBDP DAH DCSFMS KWW L8 APMX Insert Screw Wrench Anti-seizeLubricantInsert Type APX4KUR0209A16A a 3 9 2.000 2.500 .750 1.063 .415 1.918 .313 .187 1.650 TPS43 TIP15W MK1KS AOMT1848 APX4KUR2516CA22A a 4 16 2.500 3.500 1.000 1.339 .539 2.409 .375 .219 2.200 TPS43 TIP15W MK1KS * Clamp Torque (lbf-in) : TPS43=35.4 Note 1) When using inserts with corner radius Re >.126" on the bottom, B-Holders or C-Holders are required as shown on page L117. Note 2) Only corner radius Re .016" and .031" can be used for the peripheral cutting edges expect the bottom cutting edge (the end cuttting edge). Note 3) When using the tool at high spindle speeds, ensure that the tool and arbor are correctly balanced. Note 4) In case of internal coolant supply, please use a face mill arbor with through coolant channels; Regular center-thru or side-thru arbors can't be used. Note 5) The cutter body includes a non-coolant through set bolt for an arbor. L120 a : USA Stock s : Stocked in Japan