Общий каталог Mitsubishi 2020 - 2021 - страница 1250

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

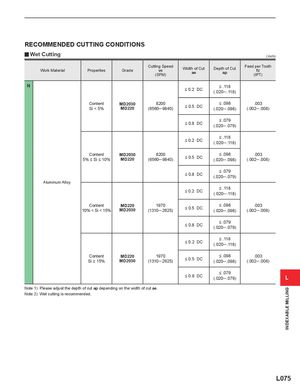

RECOMMENDED CUTTING CONDITIONS y Wet Cutting ( inch) Work Material Properties Grade Cutting Speedvc(SFM) Width of Cutae Depth of Cutap Feed per Toothfz(IPT) N ≤ 0.2 DC ≤ .118(.020─ .118) ContentSi ˂ 5% MD2030MD220 8200(6560─ 9840) ≤ 0.5 DC ≤ .098(.020─ .098).003(.002─ .008) ≤ 0.8 DC ≤ .079(.020─ .079) ≤ 0.2 DC ≤ .118(.020─ .118) Content MD20305% ≤ Si ≤ 10%MD2208200(6560─ 9840)≤ 0.5 DC ≤ .098(.020─ .098).003(.002─ .008) ≤ 0.8 DC ≤ .079(.020─ .079) Aluminum Alloy ≤ 0.2 DC ≤ .118(.020─ .118) Content MD22010% < Si < 15%MD20301970(1310─ 2625)≤ 0.5DC ≤ .098(.020─ .098).003(.002─ .008) ≤ 0.8 DC ≤ .079(.020─ .079) ≤ 0.2 DC ≤ .118(.020─ .118) ContentSi ≥ 15% MD220MD2030 1970(1310─ 2625) ≤ 0.5 DC ≤ .098(.020─ .098).003(.002─ .008) ≤ 0.8 DC ≤ .079(.020─ .079) L Note 1) Please adjust the depth of cut ap depending on the width of cut ae. Note 2) Wet cutting is recommended. L075 INDEXABLE MILLING