Общий каталог Mitsubishi 2020 - 2021 - страница 1209

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

INDEXABLE MILLING

Class

Honing

MC5020

VP15TF

NX2525

VP25N

HTi05T

MB710

MD220

R500

LLE

L

INDEXABLE MILLING

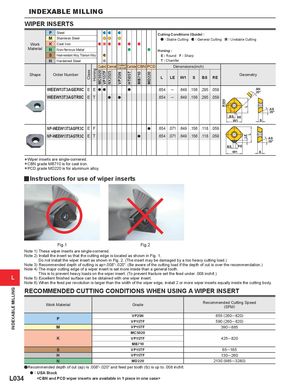

WIPER INSERTS

P Steel Cutting Conditions (Guide) :

M Stainless Steel : Stable Cutting : General Cutting : Unstable Cutting

Work K Cast Iron

Material N Non-ferrous Metal Honing :

S Heat-resistant Alloy, Titanium Alloy E : Round F : Sharp

H Hardened Steel T : Chamfer

Coated Cermet Coated Cermet Carbide CBN PCD Dimensions(inch)

Shape Order Number L LE W1 S BS RE Geometry

WEEW13T3AGER8C E E a a a .654 ─ .649 .156 .295 .059 AN20°

WEEW13T3AGTR8C E T a a .654 ─ .649 .156 .295 .059

AS

29°

BS RE

W1 S

NP-WEEW13T3AGFR3C E F a .654 .071 .649 .156 .118 .059

NP-WEEW13T3AGTR3C E T a .654 .071 .649 .156 .118 .059 AS

29°

BS RE

W1 S

Wiper inserts are single-cornered. *CBN grade MB710 is for cast iron. **PCD grade MD220 is for aluminum alloy.

yInstructions for use of wiper inserts

Fig.1 Fig.2

Note 1) These wiper inserts are single-cornered.

Note 2) Install the insert so that the cutting edge is located as shown in Fig. 1.

Do not install the wiper insert as shown in Fig. 2. (The insert may be damaged by a too heavy cutting load.)

Note 3) Recommended depth of cutting is ap=.008"-.020". (Be aware of the cutting load if the depth of cut is over the recommendation.)

Note 4) The major cutting edge of a wiper insert is set more inside than a general tooth.

This is to prevent heavy loads on the wiper insert. (To prevent fracture set the feed under .008 inch/t.)

L Note 5) Excellent finished surface can be obtained with one wiper insert.

Note 6) When the feed per revolution is larger than the width of the wiper edge, install 2 or more wiper inserts equally inside the cutting body.

RECOMMENDED CUTTING CONDITIONS WHEN USING A WIPER INSERT

Work Material Grade Recommended Cutting Speed(SFM)

P VP25NVP15TF 655 (260─ 820)590 (260─820)

M VP15TF 390 ─ 885

MC5020

K VP15TF 425─ 820

MB710

S VP15TF 65─ 165

H VP15TF 130 ─ 260

N MD220 2130 (985─ 3280)

aRecommended depth of cut (ap) is .008"-.020" and feed per tooth (fz) is up to .008 inch/t.

a : USA Stock

L034