Общий каталог Mitsubishi 2020 - 2021 - страница 1133

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

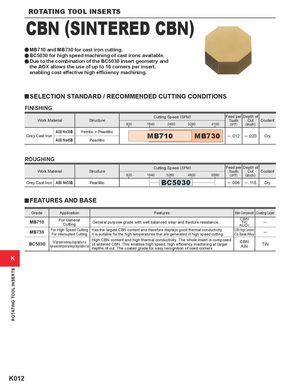

ROTATING TOOL INSERTS CBN (SINTERED CBN) a MB710 and MB730 for cast iron cutting. a BC5030 for high speed machining of cast irons available. a Due to the combination of the BC5030 insert geometry and the AOX allows the use of up to 16 corners per insert, enabling cost effective high efficiency machining. y SELECTION STANDARD / RECOMMENDED CUTTING CONDITIONS FINISHING Cutting Speed (SFM) Feed per Depth of Work Material Structure Tooth Cut Coolant 820 1640 2460 3280 4100 (IPT) (inch) AISI No35B Ferritic + Pearilitic Grey Cast Iron MB710 MB730 ─ .012 ─ .020 Dry AISI No45B Pearilitic ROUGHING Cutting Speed (SFM) Feed per Depth of Work Material Structure Tooth Cut Coolant 820 1640 3280 4920 6560 (IPT) (inch) Grey Cast Iron AISI No35B Pearilitic BC5030 ─ .006 ─ .118 Dry y FEATURES AND BASE Grade Application Features Main Component Coating Layer MB710 For GeneralCutting General purpose grade with well balanced wear and fracture resistance. CBNTiC ─Al2O3 MB730 For High Speed Cutting Has the largest CBN content and therefore displays good thermal conductivity.For interrupted CuttingIt is suitable for the high temperatures that are generated in high speed cutting.CBN (High Content)Co Base Alloy─ BC5030 For high-speed machining at large depths of cutHigh-speed interrupted machining at large depths of cutHigh CBN content and high thermal conductivity. The whole insert is composedof sintered CBN. This enables high speed, high efficiency machining at largerdepths of cut. The coated grade for easy recognition of used corners.CBNAINTiN K K012 ROTATING TOOL INSERTS