Общий каталог Mitsubishi 2020 - 2021 - страница 1114

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

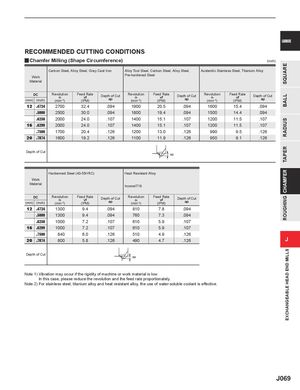

SQUAREBALLRADIUSTAPERCHAMFERROUGHINGEXCHANGEABLE HEAD END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS y Chamfer Milling (Shape Circumference) (inch) Carbon Steel, Alloy Steel, Gray Cast Iron Alloy Tool Steel, Carbon Steel, Alloy Steel, Austenitic Stainless Steel, Titanium Alloy Work Pre-hardened Steel Material DC Revolutionn(mm)(inch)(min-1)Feed Ratevf(IPM)Depth of CutapRevolutionn(min-1)Feed Ratevf(IPM)Depth of CutapRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cutap 12 .4724 2700 32.4 .094 1900 20.5 .094 1600 15.4 .094 .5000 2500 30.0 .094 1800 19.4 .094 1500 14.4 .094 .6250 2000 24.0 .107 1400 15.1 .107 1200 11.5 .107 16 .6299 2000 24.0 .107 1400 15.1 .107 1200 11.5 .107 .7500 1700 20.4 .126 1200 13.0 .126 990 9.5 .126 20 .7874 1600 19.2 .126 1100 11.9 .126 950 9.1 .126 Depth of Cut ap Hardenned Steel (40-55HRC) Heat Resistant Alloy Work Material Inconel718 DC Revolutionn(mm)(inch)(min-1)Feed Ratevf(IPM)Depth of CutapRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cutap 12 .4724 1300 9.4 .094 810 7.8 .094 .5000 1300 9.4 .094 760 7.3 .094 .6250 1000 7.2 .107 610 5.9 .107 16 .6299 1000 7.2 .107 610 5.9 .107 .7500 840 6.0 .126 510 4.9 .126 20 .7874 800 5.8 .126 490 4.7 .126 J Depth of Cut ap Note 1) Vibration may occur if the rigidity of machine or work material is low. In this case, please reduce the revolution and the feed rate proportionately. Note 2) For stainless steel, titanium alloy and heat resistant alloy, the use of water-soluble coolant is effective. J069