Общий каталог Mitsubishi 2020 - 2021 - страница 1102

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

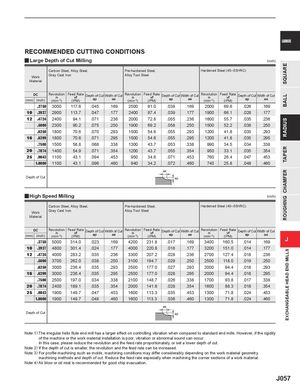

SQUAREBALLRADIUSTAPERCHAMFERROUGHINGEXCHANGEABLE HEAD END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS y Large Depth of Cut Milling (inch) Carbon Steel, Alloy Steel, Pre-hardened Steel, Hardened Steel (45─55HRC) Work Gray Cast Iron Alloy Tool Steel Material DC(mm)(inch)Revolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of CutapaeRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of CutapaeRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of Cutapae .3750 3000 117.6 .045 .169 2500 91.0 .038 .169 2000 69.6 .026 .169 10 .3937 2900 113.7 .047 .177 2400 87.4 .039 .177 1900 66.1 .028 .177 12 .4724 2400 94.1 .071 .236 2000 72.8 .055 .236 1600 55.7 .035 .236 .5000 2300 90.2 .075 .250 1900 69.2 .058 .250 1500 52.2 .038 .250 .6250 1800 70.6 .070 .293 1500 54.6 .055 .293 1200 41.8 .035 .293 16 .6299 1800 70.6 .071 .295 1500 54.6 .055 .295 1200 41.8 .035 .295 .7500 1500 58.8 .068 .338 1300 43.7 .053 .338 990 34.5 .034 .338 20 .7874 1400 54.9 .071 .354 1200 43.7 .055 .354 950 33.1 .035 .354 25 .9843 1100 43.1 .094 .453 950 34.6 .071 .453 760 26.4 .047 .453 1.0000 1100 43.1 .096 .460 940 34.2 .072 .460 740 25.8 .048 .460 ae Depth of Cut ap y High Speed Milling (inch) Carbon Steel, Alloy Steel, Pre-hardened Steel, Hardened Steel (40─55HRC) Work Gray Cast Iron Alloy Tool Steel Material DC(mm)(inch)Revolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of CutapaeRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of CutapaeRevolutionn(min-1)Feed Ratevf(IPM)Depth of Cut Width of Cutapae.37505000314.0.023.1694200231.8.017.1693400160.5.014.169J 10 .3937 4800 301.4 .024 .177 4000 220.8 .018 .177 3200 151.0 .014 .177 12 .4724 4000 283.2 .035 .236 3300 207.2 .028 .236 2700 127.4 .018 .236 .5000 3700 262.0 .038 .250 3100 194.7 .029 .250 2500 118.0 .019 .250 .6250 3000 236.4 .035 .293 2500 177.0 .027 .293 2000 94.4 .018 .293 16 .6299 3000 236.4 .035 .295 2500 177.0 .028 .295 2000 94.4 .018 .295 .7500 2500 197.0 .034 .338 2100 148.7 .026 .338 1700 93.8 .017 .338 20 .7874 2400 189.1 .035 .354 2000 141.6 .028 .354 1600 88.3 .018 .354 25 .9843 1900 149.7 .047 .453 1600 113.3 .035 .453 1300 71.8 .024 .453 1.0000 1900 149.7 .048 .460 1600 113.3 .036 .460 1300 71.8 .024 .460 ae Depth of Cut ap Note 1) The irregular helix flute end mill has a larger effect on controlling vibration when compared to standard end mills. However, if the rigidity of the machine or the work material installation is poor, vibration or abnormal sound can occur. In this case, please reduce the revolution and the feed rate proportionately, or set a lower depth of cut. Note 2) If the depth of cut is smaller, the revolution and the feed rate can be increased. Note 3) For profile machining such as molds, machining conditions may differ considerably depending on the work material geometry, machining methods and depth of cut. Reduce the feed rate especially when machining the corner sections of a work material. Note 4) Air blow or oil mist is recommended for good chip evacuation. J057