Общий каталог Mitsubishi 2020 - 2021 - страница 109

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

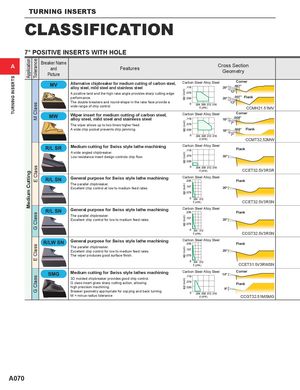

TURNING INSERTS ApplicationMedium Cutting ToleranceM ClassE ClassG ClassE ClassG Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION 7° POSITIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry Alternative chipbreaker for medium cutting of carbon steel,alloy steel, mild steel and stainless steelCarbon Steel·Alloy Steel20°Corner.007" A positive land and the high rake angle provides sharp cutting edge 12° performance. 20° .007" Flank The double breakers and round-shape in the rake face provide a 12° wide range of chip control. f (IPR) CCMH21.51MV Wiper insert for medium cutting of carbon steel,alloy steel, mild steel and stainless steelCarbon Steel·Alloy Steel Corner18°.008" The wiper allows up to two times higher feed. 7° A wide chip pocket prevents chip jamming. 18° .008" Flank 7° f (IPR) CCMT32.52MW Medium cutting for Swiss style lathe machining Carbon Steel·Alloy Steel Flank A wide angled chipbreaker. Low resistance insert design controls chip flow. 30° f (IPR) CCET32.5V3RSR General purpose for Swiss style lathe machining Carbon Steel·Alloy Steel Flank The parallel chipbreaker. Excellent chip control at low to medium feed rates. 20° f (IPR) CCET32.5V3RSN General purpose for Swiss style lathe machining Carbon Steel·Alloy Steel Flank The parallel chipbreaker. Excellent chip control for low to medium feed rates. 20° f (IPR) CCGT32.5V3RSN General purpose for Swiss style lathe machining Carbon Steel·Alloy Steel Flank The parallel chipbreaker. Excellent chip control for low to medium feed rates. 20° The wiper produces good surface finish. f (IPR) CCET31.5V3RWSN Medium cutting for Swiss style lathes machining Carbon Steel·Alloy Steel Corner14° 3D molded chipbreaker provides good chip control. G class insert gives sharp cutting action, allowing Flank high precision machining. 9° Breaker geometry appropriate for copying and back turning. M = minus radius tolerance f (IPR) CCGT32.51MSMG A070