Общий каталог Mitsubishi 2020 - 2021 - страница 107

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

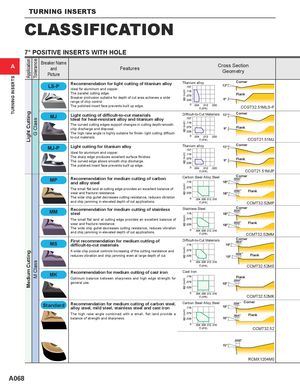

TURNING INSERTS ApplicationLight CuttingMedium Cutting ToleranceG ClassM Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION 7° POSITIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry LS-P Recommendation for light cutting of titanium alloyIdeal for aluminum and copper. Titanium alloy Corner12° The parallel cutting edge. Flank Breaker protrusion suitable for depth of cut area achieves a widerange of chip control. 6° The polished insert face prevents built up edge. f (IPR) CCGT32.51MLS-P Light cutting of difficult-to-cut materials Difficult-to-Cut Materials 13° Corner Ideal for heat-resistant alloy and titanium alloy The curved cutting edges support changes in cutting depth-smooth chip discharge and disposal. 9° Flank The high rake angle is highly suitable for finish- light cutting difficult- to-cut materials. f (IPR) CCGT21.51MJ Light cutting for titanium alloy Titanium alloy 13° Corner Ideal for aluminum and copper. The sharp edge produces excellent surface finishes.The curved edge allows smooth chip discharge. 9° Flank The polished insert face prevents built up edge. f (IPR) CCGT21.51MJP MP Recommendation for medium cutting of carbonand alloy steel Carbon Steel·Alloy Steel Corner.004" The small flat land at cutting edge provides an excellent balance ofwear and fracture resistance. .004" Flank The wide chip gullet decreases cutting resistance, reduces vibration and chip jamming in elevated depth of cut applications. f (IPR) CCMT32.52MP MM Recommendation for medium cutting of stainlesssteel Stainless Steel Corner.004" The small flat land at cutting edge provides an excellent balance of wear and fracture resistance. .004" Flank The wide chip gullet decreases cutting resistance, reduces vibration and chip jamming in elevated depth of cut applications. f (IPR) CCMT32.52MM MS First recommendation for medium cutting ofdifficult-to-cut materials Difficult-to-Cut Materials Corner.004"18° A wide chip pocket controls increasing of the cutting resistance and reduces vibration and chip jamming even at large depth of cut. 18° .004" Flank f (IPR) CCMT32.52MS MK Recommendation for medium cutting of cast iron Cast IronOptimum balance between sharpness and high edge strength forgeneral use.Flank.004"18° f (IPR) CCMT32.52MK Standard Recommendation for medium cutting of carbon steel,alloy steel, mild steel, stainless steel and cast ironCarbon Steel·Alloy Steel.004"Corner18° The high rake angle combined with a small, flat land provide abalance of strength and sharpness. 18° .004" Flank f (IPR) CCMT32.52 .008" 15° RCMX1204M0 A068