Общий каталог Mitsubishi 2020 - 2021 - страница 105

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

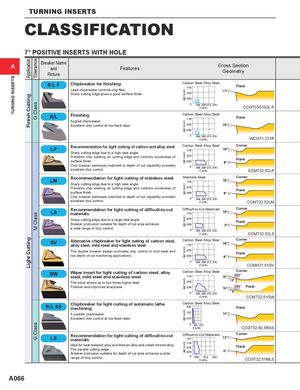

TURNING INSERTS ApplicationFinish CuttingLight Cutting ToleranceG ClassM ClassG Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION 7° POSITIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry R/L F Chipbreaker for finishing Carbon Steel·Alloy Steel Flank Lead chipbreaker controls chip flow. 17° Sharp cutting edge gives a good surface finish. f (IPR) CCGT03S102L-F Finishing Carbon Steel·Alloy Steel Flank Angled chipbreaker. Excellent chip control at low feed rates. f (IPR) WCGT1.211R LP Recommendation for light cutting of carbon and alloy steel Carbon Steel·Alloy Steel Corner Sharp cutting edge due to a high rake angle. Prevents chip welding on cutting edge and controls cloudiness ofsurface finish. Flank Chip breaker peninsula matched to depth of cut capability provides excellent chip control. f (IPR) CCMT32.52LP LM Recommendation for light cutting of stainless steel Stainless Steel Corner Sharp cutting edge due to a high rake angle. Prevents chip welding on cutting edge and controls cloudiness ofsurface finish. Flank Chip breaker peninsula matched to depth of cut capability provides excellent chip control. f (IPR) CCMT32.52LM LS Recommendation for light cutting of difficult-to-cut Difficult-to-Cut Materialsmaterials Corner Sharp cutting edge due to a large rake angle.Breaker protrusion suitable for depth of cut area achieves Flank8° a wide range of chip control. f (IPR) CCMT32.52LS Alternative chipbreaker for light cutting of carbon steel, Carbon Steel·Alloy Steel Corner alloy steel, mild steel and stainless steel The double breaker design promotes chip control in mild steel andlow depth of cut machining applications. Flank f (IPR) CCMH21.51SV Wiper insert for light cutting of carbon steel, alloysteel, mild steel and stainless steelCarbon Steel·Alloy Steel Corner20°.005" The wiper allows up to two times higher feed. 12° Positive land improves sharpness. 16° .005" Flank 8° f (IPR) CCMT32.51SW R/L SS Chipbreaker for light cutting of automatic lathemachining Carbon Steel·Alloy Steel Flank A parallel chipbreaker. 14° Excellent chip control at low feed rates. f (IPR) CCGT32.50.5RSS LS Recommendation for light cutting of difficult-to-cutmaterials Difficult-to-Cut Materials Corner12° Ideal for heat-resistant alloy and titanium alloy and cobalt chrome alloy. Flank The parallel cutting edge.Breaker protrusion suitable for depth of cut area achieves a wide 6° range of chip control. f (IPR) CCGT32.51MLS A066