Общий каталог Mitsubishi 2020 - 2021 - страница 1047

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

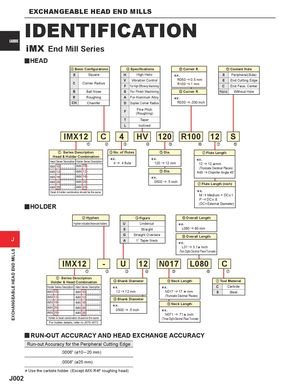

EXCHANGEABLE HEAD END MILLS IDENTIFICATION CARBIDE iMX End Mill Series yHEAD x Basic Configurations v Specifications n Corner R. , Coolant Hole S Square H High Helix ex. S Peripheral(Side) V Vibration Control R050 | 0.5 mm E End Cutting Edge C Corner Radius F For High Efficiency Machining R100 | 1 mm C End Face, Center B Ball Nose S For Finish Machining n Corner R. None Without Hole R Roughing A For Aluminum Alloy ex. CH Chamfer D Duplex Corner Radius R030 | .030 inch F Fine Pitch(Roughing) T Taper L Inclined IMX12 C 4 HV 120 R100 12 S z x c v b n m , z Series Description c No. of Flutes b Dia. m Flute Length Head & Holder Combination ex.Head Series DescriptionHolder Series Description4|4 fluteiMX 10iMX 10 -ex.120 | 12 mmex.* 12 | 12. mm (Truncate Decimal Places) iMX 12 iMX 12 - b Dia. A45 | Chamfer Angle 45° iMX 16 iMX 16 - ex. iMX 20 iMX 20 - 0500 | .5 inch m Flute Length (inch) iMX 25 iMX 25 - Head & holder combination should be the same. ex. M | Medium = DC x1 P | DC x.8 yHOLDER (DC= External Diameter) x Hyphen c Figure n Overall Length Hyphen indicates these are holders. U Undercut ex. S Straight L080 | 80 mm J G Straight Oversize n Overall LengthA1° Taper Neckex. * L31 | 3.1 inch (Two Digits Decimal Place Truncate) IMX12 - U 12 N017 L080 C z x c v b n m z Series Description Holder & Head Combination v Shank Diameter b Neck Length m Tool Material Holder Series Description Head Series Description ex. ex. C Carbide iMX 10 - iMX 10iMX 12 -iMX 12 12 | 12 mm * N017 | 17. mm(Truncate Decimal Places) S Steelv Shank Diameter iMX 16 - iMX 16iMX 20 -iMX 20 ex.0500 | .5 inchiMX 25 -iMX 25Holder & head combination should be the same.b Neck Lengthex.* N071 | .71inch(Three Digits Decimal Place Truncate) For holder details, refer to J070-J073. y RUN-OUT ACCURACY AND HEAD EXCHANGE ACCURACY Run-out Accuracy for the Peripheral Cutting Edge .0006" (ø10 ─ 20 mm) .0008" (ø25 mm) * Use the carbide holder. (Except iMX-R4F roughing head) J002 EXCHANGEABLE HEAD END MILLS