Общий каталог Mitsubishi 2020 - 2021 - страница 1034

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

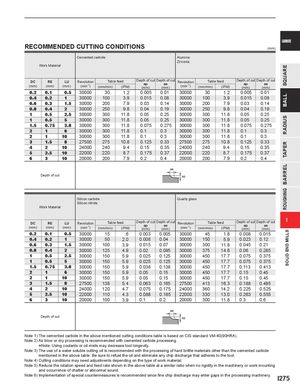

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS (mm) Cemented carbide Alumina Zirconia Work Material DC(mm) RE(mm) LU(mm) Revolution Table feed(min-1)(mm/min)(IPM)Depth of cut Depth of cutapae(mm)(mm)Revolution(min-1)Table feed(mm/min)(IPM)Depth of cut Depth of cutapae(mm)(mm) 0.2 0.1 0.5 30000 30 1.2 0.005 0.01 30000 30 1.2 0.005 0.01 0.4 0.2 1 30000 100 3.9 0.015 0.08 30000 100 3.9 0.015 0.08 0.6 0.3 1.5 30000 200 7.9 0.03 0.14 30000 200 7.9 0.03 0.14 0.8 0.4 2 30000 250 9.8 0.04 0.19 30000 250 9.8 0.04 0.19 1 0.5 2.5 30000 300 11.8 0.05 0.25 30000 300 11.8 0.05 0.25 1 0.5 5 30000 300 11.8 0.05 0.25 30000 300 11.8 0.05 0.25 1.5 0.75 3.8 30000 300 11.8 0.075 0.275 30000 300 11.8 0.075 0.275 2 1 6 30000 300 11.8 0.1 0.3 30000 300 11.8 0.1 0.3 2 1 10 30000 300 11.8 0.1 0.3 30000 300 11.8 0.1 0.3 3 1.5 8 27500 275 10.8 0.125 0.33 27500 275 10.8 0.125 0.33 4 2 10 24000 240 9.4 0.15 0.35 24000 240 9.4 0.15 0.35 5 2.5 10 22000 220 8.7 0.175 0.37 22000 220 8.7 0.175 0.37 6 3 10 20000 200 7.9 0.2 0.4 20000 200 7.9 0.2 0.4 ae Depth of cut ap Silicon carbide Quartz glass Silicon nitride Work Material DC(mm) RE(mm) LU(mm) Revolution Table feed(min-1)(mm/min)(IPM)Depth of cut Depth of cutapae(mm)(mm)Revolution(min-1)Table feed(mm/min)(IPM)Depth of cut Depth of cutapae(mm)(mm) I 0.2 0.1 0.5 30000 15 .6 0.003 0.005 30000 45 1.8 0.008 0.015 0.4 0.2 1 30000 50 2.0 0.008 0.04 30000 150 5.9 0.023 0.12 0.6 0.3 1.5 30000 100 3.9 0.015 0.07 30000 300 11.8 0.045 0.21 0.8 0.4 2 30000 125 4.9 0.02 0.095 30000 375 14.8 0.06 0.285 1 0.5 2.5 30000 150 5.9 0.025 0.125 30000 450 17.7 0.075 0.375 1 0.5 5 30000 150 5.9 0.025 0.125 30000 450 17.7 0.075 0.375 1.5 0.75 3.8 30000 150 5.9 0.038 0.138 30000 450 17.7 0.113 0.413 2 1 6 30000 150 5.9 0.05 0.15 30000 450 17.7 0.15 0.45 2 1 10 30000 150 5.9 0.05 0.15 30000 450 17.7 0.15 0.45 3 1.5 8 27500 138 5.4 0.063 0.165 27500 413 16.3 0.188 0.495 4 2 10 24000 120 4.7 0.075 0.175 24000 360 14.2 0.225 0.525 5 2.5 10 22000 110 4.3 0.088 0.185 22000 330 13.0 0.263 0.555 6 3 10 20000 100 3.9 0.1 0.2 20000 300 11.8 0.3 0.6 ae Depth of cut ap Note 1) The cemented carbide in the above mentioned cutting conditions table is based on CIS standard VM-40(90HRA). Note 2) Air blow or dry processing is recommended with cemented carbide processing. Note 3) *Note: Using coolants or oil mists The use of a water soluble cutting may oil is decrease tool longevity. recommended with the processing of hard brittle materials other than the cemented carbide mentioned in the above table. Be sure to refuel the oil and eliminate any chip discharge that adheres to the tool. Note 4) Cutting conditions may need adjustments depending on the type of work material. Note 5) Reduce the rotation speed and feed rate shown in the above table at a similar ratio when no rigidity in the machinery or work mounting and occurrence of chatter or abnormal sound. Note 6) Implementation of special countermeasures is recommended since fine chip discharge may enter gaps in the processing machinery. I275