Общий каталог Mitsubishi 2020 - 2021 - страница 103

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

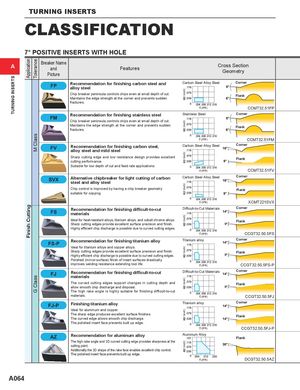

TURNING INSERTS ApplicationFinish Cutting ToleranceM ClassG Class ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch)ap (inch) TURNING INSERTS CLASSIFICATION 7° POSITIVE INSERTS WITH HOLE A Breaker Nameand FeaturesPicture Cross SectionGeometry FP Recommendation for finishing carbon steel andalloy steel Carbon Steel·Alloy Steel Corner Chip breaker peninsula controls chips even at small depth of cut.Maintains the edge strength at the corner and prevents suddenFlank fractures. f (IPR) CCMT32.51FP FM Recommendation for finishing stainless steel Stainless Steel Corner Chip breaker peninsula controls chips even at small depth of cut. Maintains the edge strength at the corner and prevents suddenfractures. Flank f (IPR) CCMT32.51FM Recommendation for finishing carbon steel, Carbon Steel·Alloy Steel Corner alloy steel and mild steel Sharp cutting edge and low resistance design provides excellentcutting performance. Flank Suitable for low depth of cut and feed rate applications. f (IPR) CCMT32.51FV Alternative chipbreaker for light cutting of carbon Carbon Steel·Alloy Steel Corner steel and alloy steel Chip control is improved by having a chip breaker geometry Flank suitable for copying. f (IPR) XCMT221SVX FS Recommendation for finishing difficult-to-cutmaterials Difficult-to-Cut Materials Corner Ideal for heat-resistant alloys, titanium alloys, and cobalt chrome alloys.Sharp cutting edges provide excellent surface precision and finish.9°Flank Highly efficient chip discharge is possible due to curved cutting edges. f (IPR) CCGT32.50.5FS FS-P Recommendation for finishing titanium alloy Titanium alloy Corner Ideal for titanium alloys and copper alloys. Sharp cutting edges provide excellent surface precision and finish.Highly efficient chip discharge is possible due to curved cutting edges.9°Flank Polished (mirror-surface) finish of insert surfaces drastically improves welding resistance extending tool life. f (IPR) CCGT32.50.5FS-P Recommendation for finishing difficult-to-cut Difficult-to-Cut Materials Corner materials The curved cutting edges support changes in cutting depth and Flank allow smooth chip discharge and disposal. 9° The high rake angle is highly suitable for finishing difficult-to-cut materials. f (IPR) CCGT32.50.5FJ Finishing titanium alloy Titanium alloy Corner Ideal for aluminum and copper. The sharp edge produces excellent surface finishes.The curved edge allows smooth chip discharge. Flank The polished insert face prevents built up edge. f (IPR) CCGT32.50.5FJ-P Recommendation for aluminum alloy Aluminum Alloy Flank The high rake angle and 3D curved cutting edge provides sharpness at the cutting point. Additionally the 3D shape of the rake face enables excellent chip control. The polished insert face prevents built up edge. f (IPR) DCGT32.50.5AZ A064