Общий каталог Mitsubishi 2020 - 2021 - страница 1010

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

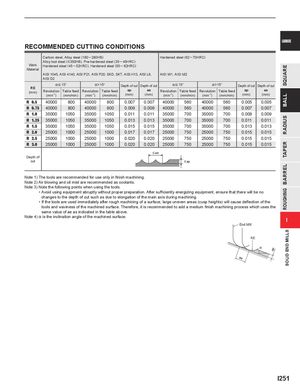

ap SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS Carbon steel, Alloy steel (180 ─ 280HB) Hardened steel (62 ─ 70HRC) Alloy tool steel (<350HB), Pre-hardened steel (35 ─ 45HRC) Work Hardened steel (45 ─ 52HRC), Hardened steel (55 ─ 62HRC) Material AISI 1045, AISI 4140, AISI P21, AISI P20, SKD, SKT, AISI H13, AISI L6, AISI W1, AISI M2 AISI D2 RE(mm) %< 15° %>15° Depth of cut Depth of cut %< 15° %>15° Depth of cut Depth of cutRevolutionTable feedRevolutionTable feedapaeRevolutionTable feedRevolutionTable feedapae(min-1)(mm/min)(min-1)(mm/min)(mm)(mm)(min-1)(mm/min)(min-1)(mm/min)(mm)(mm) R 0.5 40000 800 40000 800 0.007 0.007 40000 560 40000 560 0.005 0.005 R 0.75 40000 800 40000 800 0.009 0.009 40000 560 40000 560 0.007 0.007 R 1.0 35000 1050 35000 1050 0.011 0.011 35000 700 35000 700 0.009 0.009 R 1.25 35000 1050 35000 1050 0.013 0.013 35000 700 35000 700 0.011 0.011 R 1.5 35000 1050 35000 1050 0.015 0.015 35000 700 35000 700 0.013 0.013 R 2.0 25000 1000 25000 1000 0.017 0.017 25000 750 25000 750 0.015 0.015 R 2.5 25000 1000 25000 1000 0.020 0.020 25000 750 25000 750 0.015 0.015 R 3.0 25000 1000 25000 1000 0.020 0.020 25000 750 25000 750 0.015 0.015 < ae Depth of cut < ap Note 1) The tools are recommended for use only in finish machining. Note 2) Air blowing and oil mist are recommended as coolants. Note 3) Note the following points when using the tools. • Avoid using equipment abruptly without proper preparation. After sufficiently energizing equipment, ensure that there will be no changes to the depth of cut such as due to elongation of the main axis during machining. • If the tools are used immediately after rough machining of a surface, large uneven areas (cusp heights) will cause deflection of the tools and waviness of the machined surface. Therefore, it is recommended to add a medium finish machining process which uses the same value of ae as indicated in the table above. Note 4) % is the inclination angle of the machined surface. I End Mill RE % ae I251