Общий каталог Lamina Technologies 2019 - 2020 - страница 26

Навигация

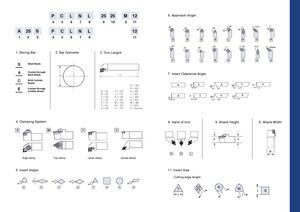

EXTERNAL TURNING TOOL HOLDERS EXTERNAL TURNING TOOL HOLDERS P C L N L 25 25 M 12 6. Approach Angle 4 5 6 7 8 9 10 3 11 A 25 S P C L N L 12 90° 75° 45° 95°80°95° 62.5° 107.5° 75° 1 2 3 4 5 6 7 8 11 D B D E L N Q R 90° 91° 93° 75° 93° 72.5° Special 45° 1. Boring Bar 2. Bar Diameter 3. Tool Lenght F G J K S U V X S Steel Shank A Coolant throughSteel Shank d l1 7. Insert Clearance Angle C Solid CarbideShankECoolant throughCarbide Shank Q = 180R = 200 N 3° A 20° E 25° F 11° PA = 32H = 100S = 250 B = 40 J = 110 T = 300C = 50K = 125U = 350D = 60L = 140V = 400 B5° 7° C 30° G 15° D E = 70 M = 150 W = 450 F = 80 N = 160 Y = 500 G = 90 P = 170 X = Special 4. Clamping System 8. Hand of tool 9. Shank Height 9. Shank Width D M P S h h b R N L Rigit clamp Top clamp Lever clamp Screw clamp 5. Insert shape 11. Insert Size Cutting edge lenght 35° 80° 55° 80° 60° 55° D V C D T S R K Tl CDEV l R l W l Sl 48 49

Общий каталог Lamina Technologies 2017 - 2018

Общий каталог Lamina Technologies 2017 - 2018