Каталог Kemmler цанговые патроны KPS - страница 14

Навигация

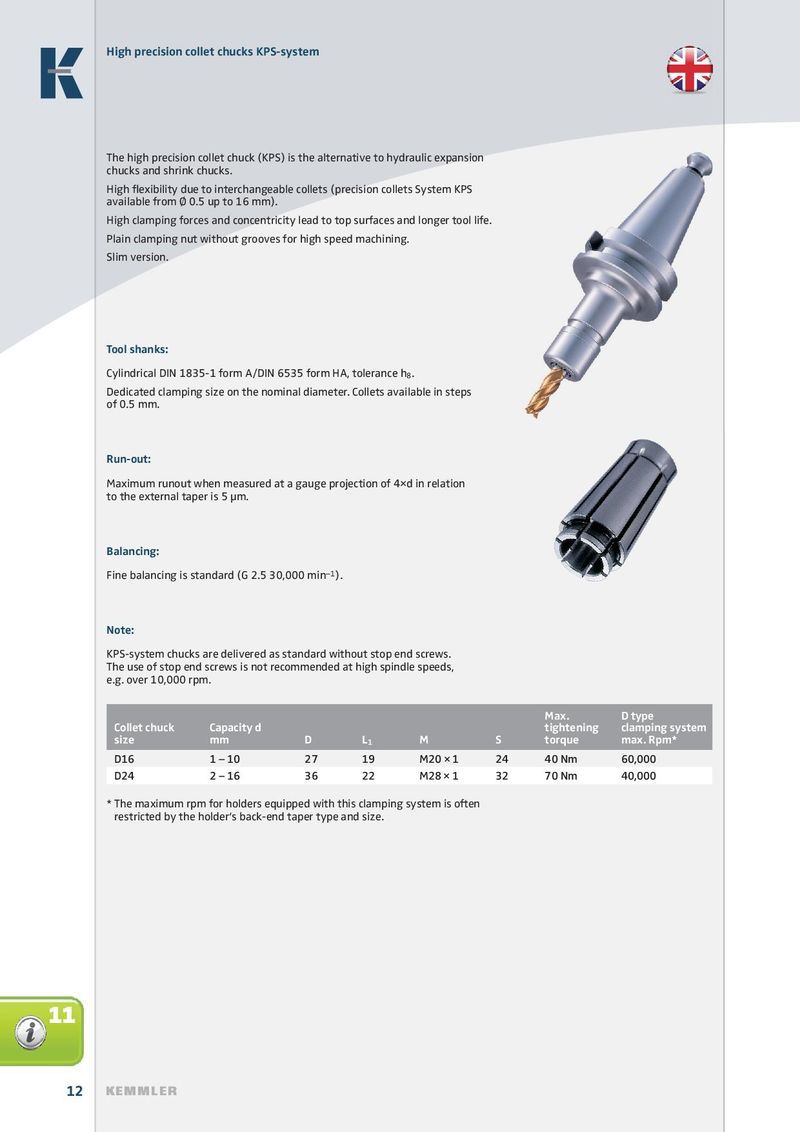

High precision collet chucks KPS-system The high precision collet chuck (KPS) is the alternative to hydraulic expansion chucks and shrink chucks. High fl exibility due to interchangeable collets (precision collets System KPS available from Ø 0.5 up to 16 mm). High clamping forces and concentricity lead to top surfaces and longer tool life. Plain clamping nut without grooves for high speed machining. Slim version. Tool shanks: Cylindrical DIN 1835-1 form A/DIN 6535 form HA, tolerance h 8 . Dedicated clamping size on the nominal diameter. Collets available in steps of 0.5 mm. Run-out: Maximum runout when measured at a gauge projection of 4×d in relation to the external taper is 5 µm. Balancing: Fine balancing is standard (G 2.5 30,000 min –1 ). Note: KPS-system chucks are delivered as standard without stop end screws. The use of stop end screws is not recommended at high spindle speeds, e.g. over 10,000 rpm. Max. D type Collet chuck Capacity d tightening clamping system size mm D L 1 M S torque max. Rpm* D16 1 – 10 27 19 M20 × 1 24 40 Nm 60,000 D24 2 – 16 36 22 M28 × 1 32 70 Nm 40,000 * The maximum rpm for holders equipped with this clamping system is often restricted by the holder‘s back-end taper type and size. 11 12 KEMMLER KEMMLER

Каталог Kemmler усадочные патроны и усадочная техника

Каталог Kemmler усадочные патроны и усадочная техника Каталог Kemmler резьбонарезные патроны

Каталог Kemmler резьбонарезные патроны Каталог Kemmler гидроразжимные патроны

Каталог Kemmler гидроразжимные патроны Общий каталог Kemmler 2017 - 2018

Общий каталог Kemmler 2017 - 2018 Общий каталог Kemmler 2020

Общий каталог Kemmler 2020