Каталог Iscar вращающийся инструмент 2017 - страница 91

Навигация

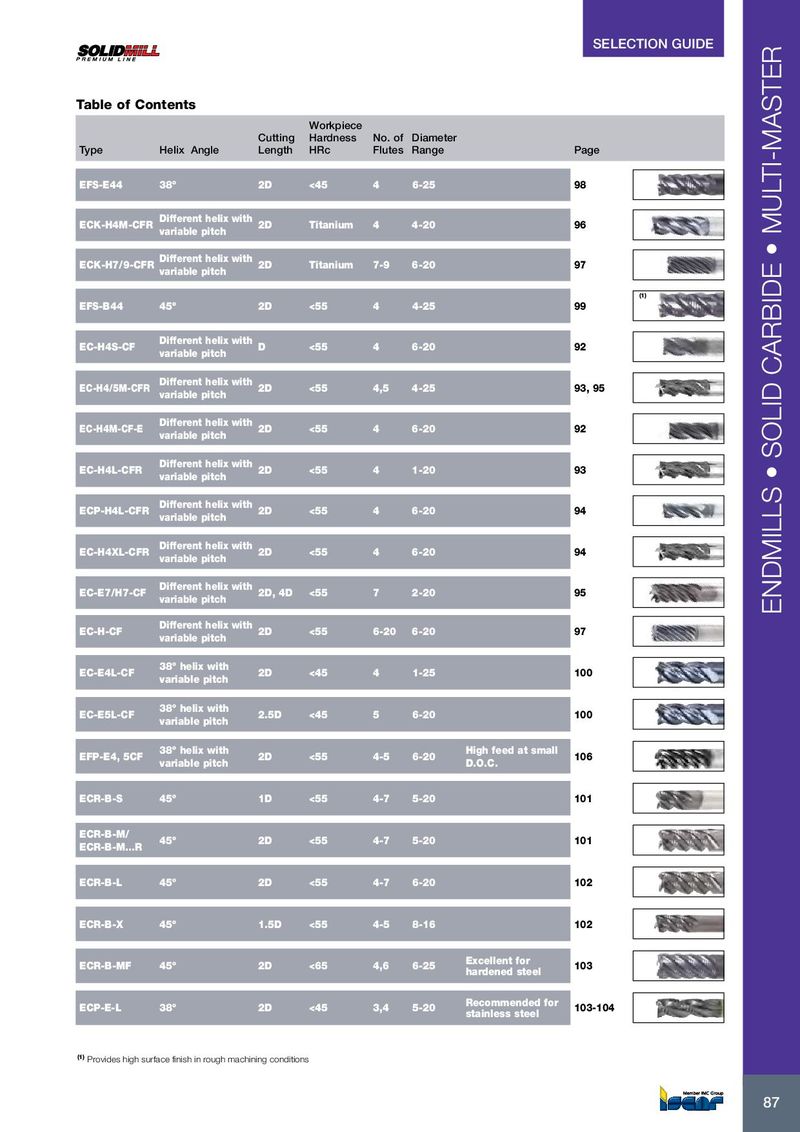

SELECTION GUIDE Table of Contents Workpiece Cutting Hardness No. of Diameter Type Helix Angle Length HRc Flutes Range Page EFS-E44 38º 2D <45 4 6-25 98 Different helix with ECK-H4M-CFR 2D Titanium 4 4-20 96 variable pitch Different helix with ECK-H7/9-CFR 2D Titanium 7-9 6-20 97 variable pitch (1) EFS-B44 45º 2D <55 4 4-25 99 Different helix with EC-H4S-CF D <55 4 6-20 92 variable pitch Different helix with EC-H4/5M-CFR 2D <55 4,5 4-25 93, 95 variable pitch Different helix with EC-H4M-CF-E 2D <55 4 6-20 92 variable pitch Different helix with EC-H4L-CFR 2D <55 4 1-20 93 variable pitch Different helix with ECP-H4L-CFR 2D <55 4 6-20 94 variable pitch Different helix with EC-H4XL-CFR 2D <55 4 6-20 94 variable pitch Different helix with EC-E7/H7-CF 2D, 4D <55 7 2-20 95 variable pitch ENDMILLS • SOLID CARBIDE • MULTI-MASTER Different helix with EC-H-CF 2D <55 6-20 6-20 97 variable pitch 38º helix with EC-E4L-CF 2D <45 4 1-25 100 variable pitch 38º helix with EC-E5L-CF 2.5D <45 5 6-20 100 variable pitch 38º helix with High feed at small EFP-E4, 5CF 2D <55 4-5 6-20 106 variable pitch D.O.C. ECR-B-S 45º 1D <55 4-7 5-20 101 ECR-B-M/ 45º 2D <55 4-7 5-20 101 ECR-B-M...R ECR-B-L 45º 2D <55 4-7 6-20 102 ECR-B-X 45º 1.5D <55 4-5 8-16 102 Excellent for ECR-B-MF 45º 2D <65 4,6 6-25 103 hardened steel Recommended for ECP-E-L 38º 2D <45 3,4 5-20 103-104 stainless steel (1) Provides high surface finish in rough machining conditions 87 87

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022