Каталог Iscar вращающийся инструмент 2017 - страница 87

Навигация

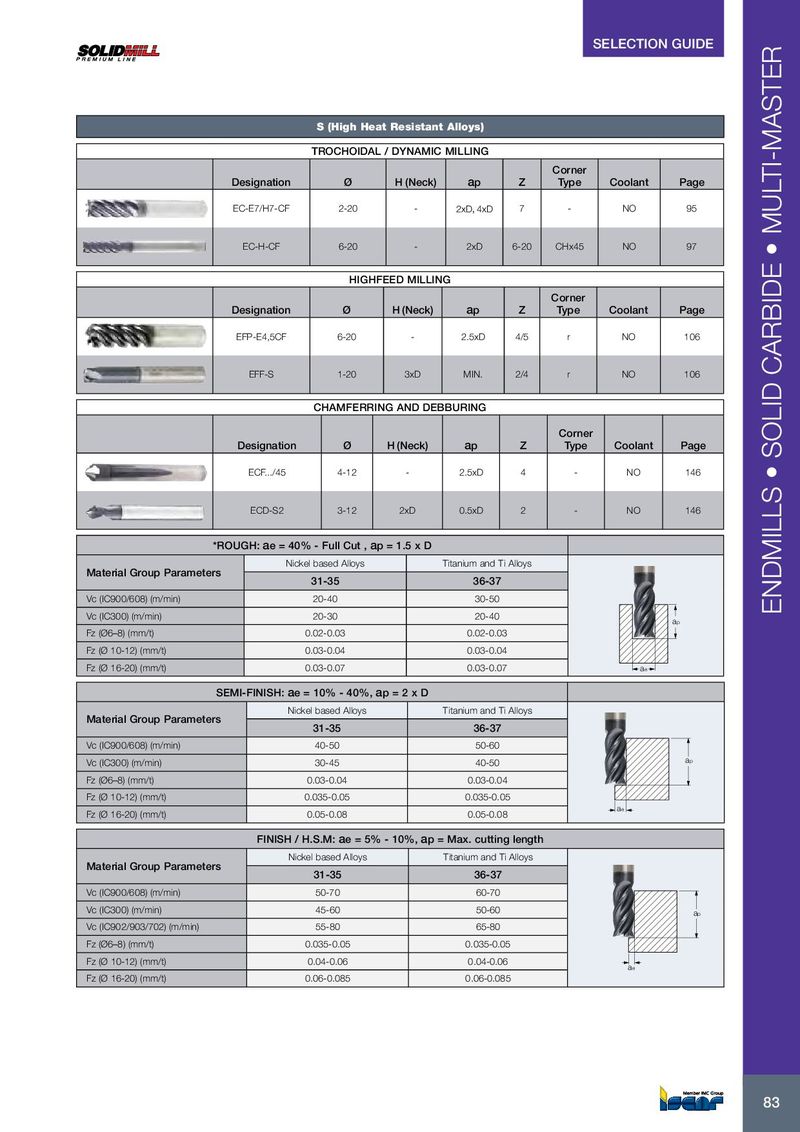

SELECTION GUIDE S (High Heat Resistant Alloys) TROCHOIDAL / DYNAMIC MILLING Corner Designation Ø H (Neck) ap Z Type Coolant Page EC-E7/H7-CF 2-20 - 2xD, 4xD 7 - NO 95 EC-H-CF 6-20 - 2xD 6-20 CHx45 NO 97 HIGHFEED MILLING Corner Designation Ø H (Neck) ap Z Type Coolant Page EFP-E4,5CF 6-20 - 2.5xD 4/5 r NO 106 EFF-S 1-20 3xD MIN. 2/4 r NO 106 CHAMFERRING AND DEBBURING Corner Designation Ø H (Neck) ap Z Type Coolant Page ECF.../45 4-12 - 2.5xD 4 - NO 146 ECD-S2 3-12 2xD 0.5xD 2 - NO 146 *ROUGH: ae = 40% - Full Cut , ap = 1.5 x D Nickel based Alloys Titanium and Ti Alloys Material Group Parameters 31-35 36-37 Vc (IC900/608) (m/min) 20-40 30-50 ENDMILLS • SOLID CARBIDE • MULTI-MASTER Vc (IC300) (m/min) 20-30 20-40 ap Fz (Ø6–8) (mm/t) 0.02-0.03 0.02-0.03 Fz (Ø 10-12) (mm/t) 0.03-0.04 0.03-0.04 Fz (Ø 16-20) (mm/t) 0.03-0.07 0.03-0.07 ae SEMI-FINISH: ae = 10% - 40%, ap = 2 x D Nickel based Alloys Titanium and Ti Alloys Material Group Parameters 31-35 36-37 Vc (IC900/608) (m/min) 40-50 50-60 Vc (IC300) (m/min) 30-45 40-50 ap Fz (Ø6–8) (mm/t) 0.03-0.04 0.03-0.04 Fz (Ø 10-12) (mm/t) 0.035-0.05 0.035-0.05 ae Fz (Ø 16-20) (mm/t) 0.05-0.08 0.05-0.08 FINISH / H.S.M: ae = 5% - 10%, ap = Max. cutting length Nickel based Alloys Titanium and Ti Alloys Material Group Parameters 31-35 36-37 Vc (IC900/608) (m/min) 50-70 60-70 Vc (IC300) (m/min) 45-60 50-60 ap Vc (IC902/903/702) (m/min) 55-80 65-80 Fz (Ø6–8) (mm/t) 0.035-0.05 0.035-0.05 Fz (Ø 10-12) (mm/t) 0.04-0.06 0.04-0.06 ae Fz (Ø 16-20) (mm/t) 0.06-0.085 0.06-0.085 83 83

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022