Каталог Iscar вращающийся инструмент 2017 - страница 13

Навигация

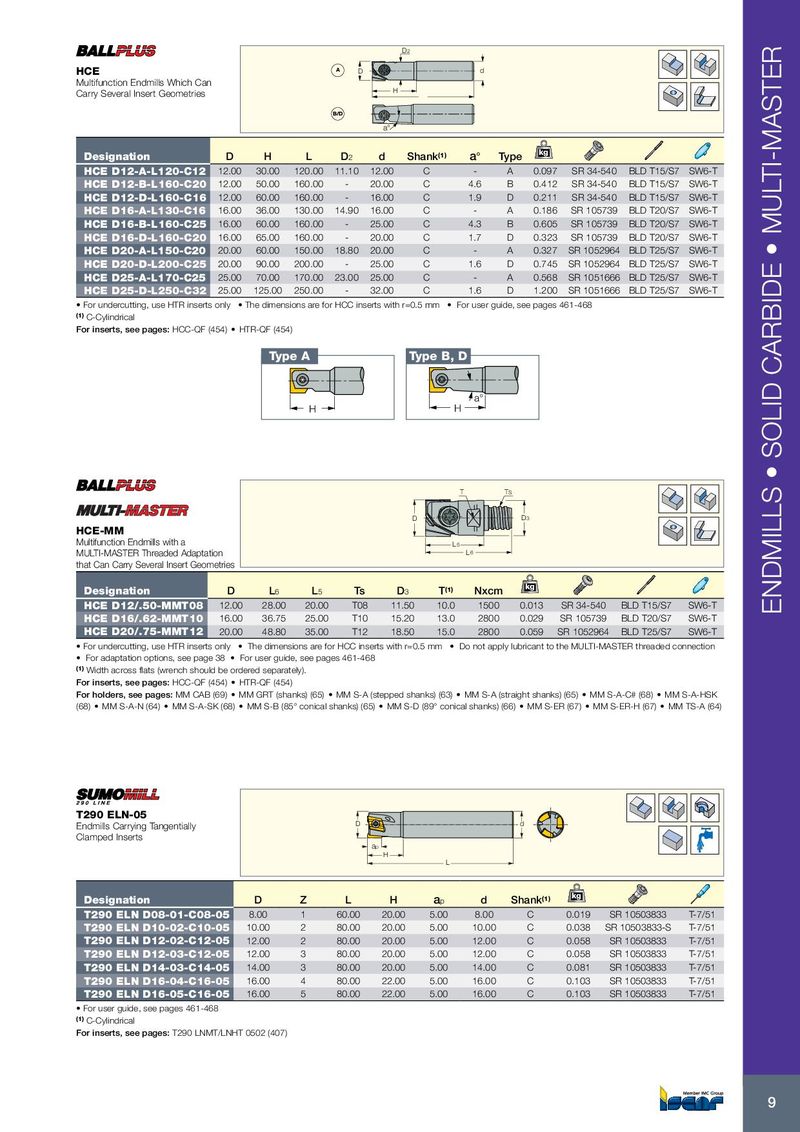

D 2 HCE A D d Multifunction Endmills Which Can H Carry Several Insert Geometries B/D a° kg Designation D H L D 2 d Shank (1) a° Type HCE D12-A-L120-C12 12.00 30.00 120.00 11.10 12.00 C - A 0.097 SR 34-540 BLD T15/S7 SW6-T HCE D12-B-L160-C20 12.00 50.00 160.00 - 20.00 C 4.6 B 0.412 SR 34-540 BLD T15/S7 SW6-T HCE D12-D-L160-C16 12.00 60.00 160.00 - 16.00 C 1.9 D 0.211 SR 34-540 BLD T15/S7 SW6-T HCE D16-A-L130-C16 16.00 36.00 130.00 14.90 16.00 C - A 0.186 SR 105739 BLD T20/S7 SW6-T HCE D16-B-L160-C25 16.00 60.00 160.00 - 25.00 C 4.3 B 0.605 SR 105739 BLD T20/S7 SW6-T HCE D16-D-L160-C20 16.00 65.00 160.00 - 20.00 C 1.7 D 0.323 SR 105739 BLD T20/S7 SW6-T HCE D20-A-L150-C20 20.00 60.00 150.00 18.80 20.00 C - A 0.327 SR 1052964 BLD T25/S7 SW6-T HCE D20-D-L200-C25 20.00 90.00 200.00 - 25.00 C 1.6 D 0.745 SR 1052964 BLD T25/S7 SW6-T HCE D25-A-L170-C25 25.00 70.00 170.00 23.00 25.00 C - A 0.568 SR 1051666 BLD T25/S7 SW6-T HCE D25-D-L250-C32 25.00 125.00 250.00 - 32.00 C 1.6 D 1.200 SR 1051666 BLD T25/S7 SW6-T • For undercutting, use HTR inserts only • The dimensions are for HCC inserts with r=0.5 mm • For user guide, see pages 461-468 (1) C-Cylindrical For inserts, see pages: HCC-QF (454) • HTR-QF (454) Type A Type B, D a° H H T T S D D 3 HCE-MM Multifunction Endmills with a L 5 MULTI-MASTER Threaded Adaptation L 6 that Can Carry Several Insert Geometries Designation D L 6 L 5 Ts D 3 T (1) kg Nxcm HCE D12/.50-MMT08 12.00 28.00 20.00 T08 11.50 10.0 1500 0.013 SR 34-540 BLD T15/S7 SW6-T ENDMILLS • SOLID CARBIDE • MULTI-MASTER HCE D16/.62-MMT10 16.00 36.75 25.00 T10 15.20 13.0 2800 0.029 SR 105739 BLD T20/S7 SW6-T HCE D20/.75-MMT12 20.00 48.80 35.00 T12 18.50 15.0 2800 0.059 SR 1052964 BLD T25/S7 SW6-T • For undercutting, use HTR inserts only • The dimensions are for HCC inserts with r=0.5 mm • Do not apply lubricant to the MULTI-MASTER threaded connection • For adaptation options, see page 38 • For user guide, see pages 461-468 (1) Width across flats (wrench should be ordered separately). For inserts, see pages: HCC-QF (454) • HTR-QF (454) For holders, see pages: MM CAB (69) • MM GRT (shanks) (65) • MM S-A (stepped shanks) (63) • MM S-A (straight shanks) (65) • MM S-A-C# (68) • MM S-A-HSK (68) • MM S-A-N (64) • MM S-A-SK (68) • MM S-B (85° conical shanks) (65) • MM S-D (89° conical shanks) (66) • MM S-ER (67) • MM S-ER-H (67) • MM TS-A (64) T290 ELN-05 Endmills Carrying Tangentially D d Clamped Inserts ap H L kg Designation D Z L H a p d Shank (1) T290 ELN D08-01-C08-05 8.00 1 60.00 20.00 5.00 8.00 C 0.019 SR 10503833 T-7/51 T290 ELN D10-02-C10-05 10.00 2 80.00 20.00 5.00 10.00 C 0.038 SR 10503833-S T-7/51 T290 ELN D12-02-C12-05 12.00 2 80.00 20.00 5.00 12.00 C 0.058 SR 10503833 T-7/51 T290 ELN D12-03-C12-05 12.00 3 80.00 20.00 5.00 12.00 C 0.058 SR 10503833 T-7/51 T290 ELN D14-03-C14-05 14.00 3 80.00 20.00 5.00 14.00 C 0.081 SR 10503833 T-7/51 T290 ELN D16-04-C16-05 16.00 4 80.00 22.00 5.00 16.00 C 0.103 SR 10503833 T-7/51 T290 ELN D16-05-C16-05 16.00 5 80.00 22.00 5.00 16.00 C 0.103 SR 10503833 T-7/51 • For user guide, see pages 461-468 (1) C-Cylindrical For inserts, see pages: T290 LNMT/LNHT 0502 (407) 9

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022